Copper pyrometallurgy and hydrometallurgy processes represent the two fundamental technological pathways for extracting copper metal from its ores. Selecting the optimal method depends heavily on the ore type, mineralogy, economic factors, and increasingly, environmental considerations. Understanding the core principles, stages, and key differences between pyrometallurgical and hydrometallurgical copper extraction is crucial for mining operations, smelters, and industries sourcing refined copper.

Copper Pyrometallurgy and Hydrometallurgy Processes

Copper extraction technologies are broadly classified into two main categories: pyrometallurgy and hydrometallurgy. Currently, over 80% of the world’s primary copper is produced using pyrometallurgical copper production processes.

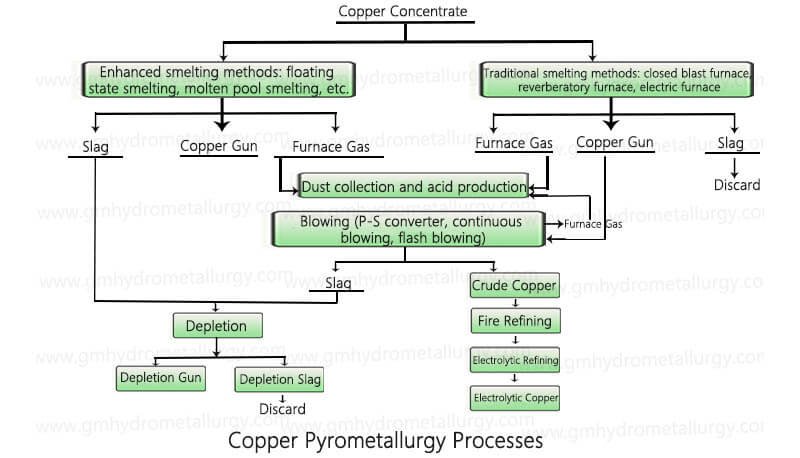

I. Pyrometallurgical Copper Extraction (High-Temperature Processing)

Pyrometallurgy utilizes high-temperature furnaces to chemically convert copper sulfide ores (like chalcopyrite – CuFeS₂) into metallic copper through a series of steps:

Advantages of Pyrometallurgy:

High efficiency and throughput for large-scale operations.

Well-established, mature technology.

Suitable for primary sulfide ores (the most abundant copper source).

Produces high-purity copper via electrorefining.

Recovers valuable by-products (sulfuric acid, precious metals from slimes).

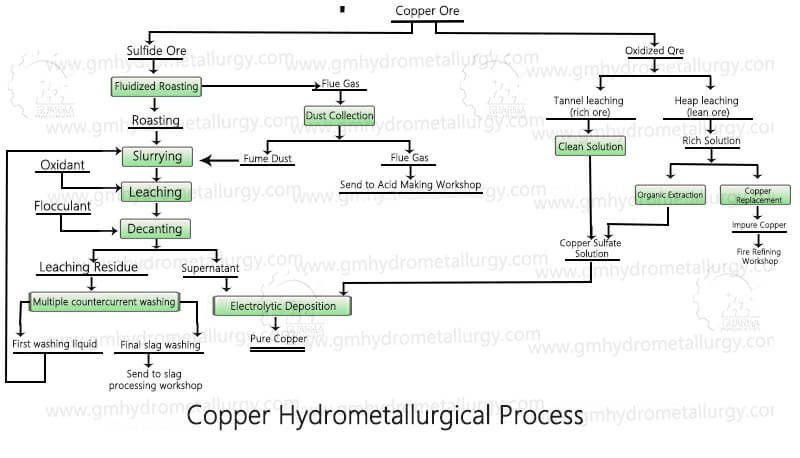

Hydrometallurgical copper extraction is a method that utilizes solvents to dissolve copper from copper ore, concentrates, or calcine. The copper is then concentrated and recovered through solution purification and separation from impurities. A flowchart depicting the hydrometallurgical copper extraction process is shown below / is provided in the diagram.

II. Hydrometallurgical Copper Extraction (Chemical Leaching)

Hydrometallurgy uses aqueous chemical solutions to dissolve copper from the ore at relatively low temperatures, followed by purification and recovery. It’s particularly suited for oxide ores (like malachite, azurite), low-grade sulfide ores, and mine waste.

Advantages of Hydrometallurgy:

Lower energy consumption (especially for heap leaching/EW).

Lower capital costs for heap/dump leaching operations.

Environmentally preferable: Lower SO₂ emissions (no smelting/converting), potential for lower CO₂ footprint.

Suitable for low-grade ores, oxide ores, and mine waste that pyrometallurgy cannot economically process.

Produces very high-purity cathode copper directly.

Modular and scalable, especially SX-EW.

Choosing Between Pyrometallurgy and Hydrometallurgy:

Sulfide Ores (Primary): Pyrometallurgy is generally the primary route, especially for high-grade concentrates. Hydrometallurgy (often bioleaching/SX-EW) is increasingly used for low-grade sulfides or where environmental constraints are severe.

Oxide Ores / Mixed Ores: Hydrometallurgy (acid leaching/SX-EW) is the standard and most economical method.

Secondary Materials (Scrap): Primarily processed via pyrometallurgy (re-melting, refining).

Partner with Experts in Copper Production

Mastering copper pyrometallurgy and hydrometallurgy processes is fundamental to efficient and responsible copper production. Whether your project involves primary sulfide concentrates, complex oxide ores, or sustainable resource recovery, selecting and optimizing the right extraction path is critical.

Guanma Machinery leverages deep expertise in both pyrometallurgical and hydrometallurgical technologies. We partner with mining and processing operations globally, providing technical consulting, process optimization solutions, and supplying high-quality reagents or equipment tailored to your specific ore body and operational goals.

Optimize your copper extraction strategy. Contact Guanma Machinery today to discuss how our expertise in pyrometallurgy and hydrometallurgy can enhance your operations.