Struggling to transform scrap gold, jewelry, or mined ore into pure, investment-grade precious metal? Understanding the right gold refining methods is absolutely crucial. Whether you’re a jeweler, recycler, miner, or investor, achieving high purity (often 99.5% to 99.99%+) maximizes value and opens doors to global markets.

1. Chemical Refining: Precision Through Reaction

The most common approach for smaller scales and diverse feed materials involves selective chemical reactions.

Aqua Regia Process: The classic method for high-purity results (up to 99.95%+). It dissolves gold using a potent mix of hydrochloric acid (HCl) and nitric acid (HNO₃). Subsequent steps involve careful precipitation or solvent extraction to recover the pure gold.

Ideal for: Jewelry scrap, electronic gold recovery (e-waste), dental gold, yielding high purity.

Key Considerations: Requires stringent safety protocols for handling dangerous acids and fumes. Efficient fume scrubbers and neutralization systems are essential for environmental compliance and operator safety.

Acid / Peroxide (AP) Leaching: A safer alternative for specific materials like electronic components, selectively dissolving base metals and leaving gold foils intact.

Ideal for: Initial treatment of e-waste before further refining.

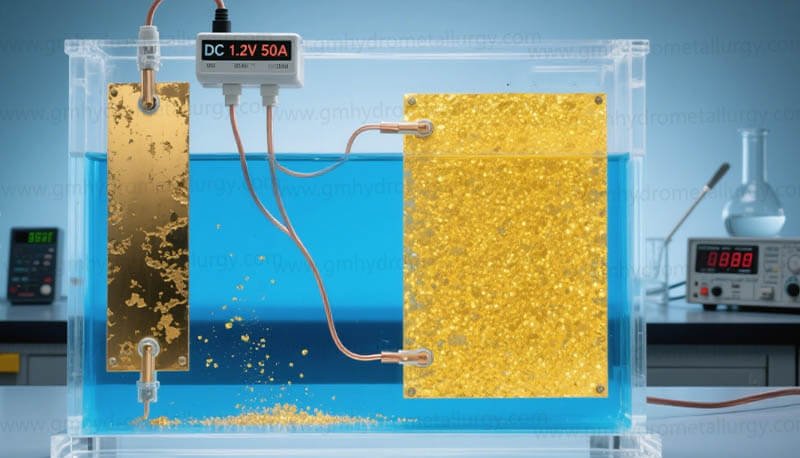

2. Electrolytic Refining: The Gold Standard for Pure Bullion

For large-scale operations and achieving the ultimate purity (99.99%+), electrolysis reigns supreme.

Wohlwill Process: The benchmark for producing 24-karat gold and Good Delivery bars. Impure gold anodes are dissolved in an electrolyte (chloride solution). Pure gold migrates and deposits onto stainless steel cathodes, leaving impurities behind.

Ideal for: Major refineries, central banks, producing large volumes of investment-grade gold.

Key Considerations: Demands significant capital investment in specialized tanks, rectifiers, and electrolyte management systems.

Inquartation & Parting: Often a precursor to electrolysis or chemical refining for low-karat alloys. Gold is alloyed with silver (inquartation) to a specific ratio, then dissolved in nitric acid, which removes the silver and base metals, leaving porous gold.

Ideal for: Processing low-karat gold alloys effectively.

3. Pyrometallurgical (Fire) Refining: Heat-Driven Separation

Utilizing extreme heat, these methods are robust for bulk processing.

Miller Chlorination: Highly efficient for large volumes. Molten impure gold is treated with chlorine gas. Base metals form volatile chlorides and are removed, while gold remains. Achieves purities around 99.5%.

Ideal for: Primary gold producers and large-scale refiners treating doré bullion.

Key Considerations: Requires high-temperature furnaces (exceeding 1100°C), sophisticated gas handling, and emission control systems (scrubbers).

Cupellation: An ancient method still used for specific applications, separating gold from lead or lead-silver alloys in a cupel (bone ash cup) under high heat. Oxygen oxidizes the lead, which absorbs into the cupel.

Choosing the Right Method: Key Factors for Your Business

Selecting the optimal gold refining method depends on critical variables:

Feed Material: Scrap jewelry, doré bars, e-waste, mining concentrates?

Required Purity: Investment bullion (99.99%+), jewelry alloy (99.5%)?

Scale & Budget: Small batch processing or continuous industrial throughput?

Safety & Environmental Compliance: Can you manage hazardous chemicals or gases?

Desired By-Product Recovery: Is reclaiming silver, platinum group metals (PGMs), or copper important?

Partnering for Refining Success

Mastering gold refining methods is fundamental to unlocking the true value in your gold-bearing materials. From the chemical precision of Aqua Regia to the industrial power of Miller Chlorination and the ultimate purity of the Wohlwill process, each technique has its place. Understanding these processes empowers you to make informed decisions, whether setting up your own operation or selecting a refining partner.

Ready to transform your gold into its purest, most valuable form? Explore our advanced, efficient, and safe gold refining solutions designed for professional results.