Lead is one of the most widely used non-ferrous metals, known for its versatility and unique physical properties. However, the lead we obtain from ores or recycling isn’t pure enough for direct use in industries. That’s where the refining process comes in. Lead refining ensures that impurities like silver, bismuth, antimony, copper, and others are removed, producing a high-purity material suitable for batteries, radiation shielding, and countless industrial applications.

Understanding Lead

Lead naturally occurs in the Earth’s crust, mostly in the form of galena (PbS). While abundant, crude lead is far from pure. Once extracted, it contains impurities that can hinder its usability. Refined lead, on the other hand, finds use in automotive batteries, construction materials, protective shielding, and electronics.

Why Lead Needs Refining?

Crude lead contains unwanted elements such as copper, silver, gold, arsenic, and bismuth. These impurities can affect hardness, conductivity, and corrosion resistance. For example, battery manufacturers demand lead with purity levels above 99.99%, which is only achievable through careful refining.

Overview of Lead Refining Process

There are two main refining routes:

Pyrometallurgical refining – based on heat and chemical reactions.

Electrolytic refining – based on electricity and chemical dissolution.

Each method has its own advantages and is chosen depending on the desired purity, scale, and type of lead being processed.

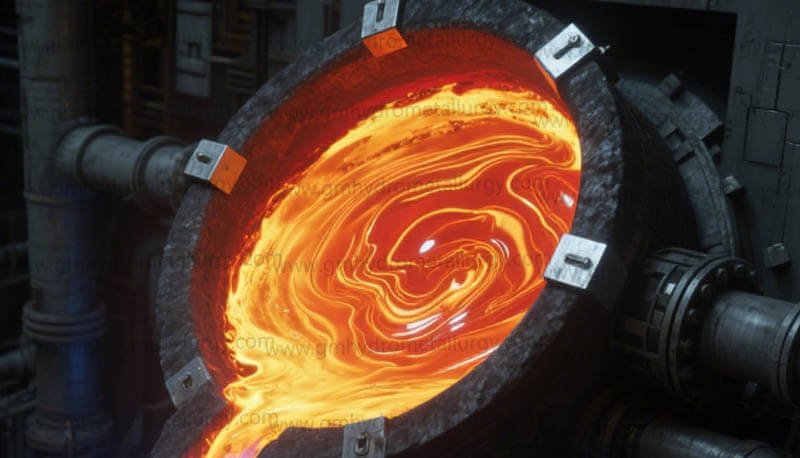

Pyrometallurgical Lead Refining

This is the most common method. It relies on heating crude lead and using additives to separate impurities.

Drossing Process

When molten lead is stirred, oxygen reacts with metal impurities forming oxides (called dross), which are skimmed off the surface.

Softening Process

Antimony, arsenic, and tin are removed by oxidation. This makes the lead “softer” and closer to the required purity.

Desilverization Process

Silver impurities are removed, typically using the Parkes process, which involves adding zinc that preferentially combines with silver.

Electrolytic Lead Refining

This technique provides extremely pure lead (up to 99.999%).

Anode: Impure lead slabs.

Cathode: Thin sheets of pure lead.

Electrolyte: Lead fluorosilicate solution with fluosilicic acid.

When current passes through, pure lead deposits on the cathode while impurities fall off as “anode slime.” This slime often contains precious metals like silver and gold, making electrolytic refining economically beneficial.

Cupellation Process

Historically used for separating precious metals from lead, cupellation involves high-temperature oxidation in a porous vessel. While largely outdated, it still has niche uses in refining processes where silver content is high.

Parkes Process

In this process, zinc is added to molten lead. Silver dissolves in zinc, forming a separate layer that can be removed. This is a crucial step in refining because silver contamination is common in crude lead.

Refining Secondary (Recycled) Lead

Recycling is now a major source of refined lead, especially from lead-acid batteries. Secondary refining involves smelting scrap lead and removing contaminants. This reduces the need for mining, making it a more sustainable option.

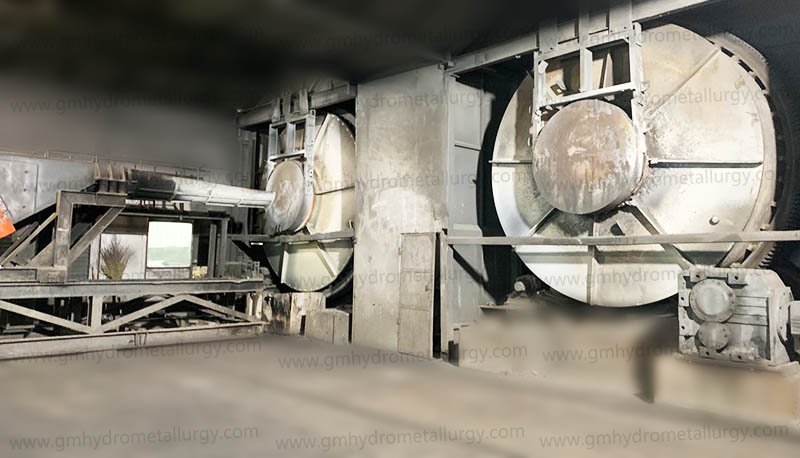

Lead Refining Equipment

Blast Furnaces & Reverberatory Furnaces – for smelting.

Electrolytic Cells – for high-purity refining.

Pollution Control Systems – dust collectors, scrubbers, and filters.

Applications of Refined Lead

Batteries: The largest market share, particularly lead-acid batteries.

Radiation Shielding: In hospitals, laboratories, and nuclear plants.

Alloys: For soldering, bearings, and construction.

The process of lead refining is vital for producing high-purity lead used in countless applications worldwide. From traditional pyrometallurgical methods to advanced electrolytic refining, each technique plays a role in meeting global demand. As industries grow, sustainable refining practices will shape the future of this essential metal.