For businesses serious about gold purity, scalability, and efficient refining, understanding the gold electrolysis system is crucial. If you’re sourcing refining technology or seeking reliable partners for large-scale operations, this deep dive into electrolytic systems is essential.

How the Gold Electrolysis System Works (The Core Process)

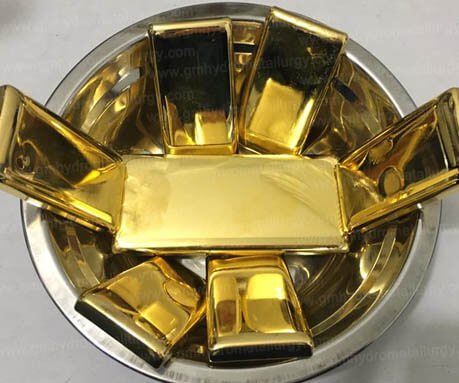

1. Anode Preparation

Crude or partially refined gold (typically cast into bars) becomes the anode (positive electrode). This contains the gold plus impurities.

2. Electrolyte Solution

A specific chemical bath, usually hydrochloric acid (HCl) mixed with gold chloride (AuCl3), fills the cell. This solution conducts electricity and carries gold ions.

3. Applying Current

Direct current (DC) electricity is applied. At the anode, gold (and some impurities) dissolve into the electrolyte as ions: Au -> Au³⁺ + 3e⁻.

4. Selective Deposition

At the cathode (negative electrode, often made of pure titanium or stainless steel), only the gold ions preferentially reduce back into solid, ultra-pure metal: Au³⁺ + 3e⁻ -> Au. Most impurities either remain dissolved in the electrolyte or fall to the bottom as anode slimes/sludge.

5. Collection

Pure gold crystals or sheets form on the cathode, harvested periodically. The valuable anode slime (containing PGMs like platinum and palladium) is processed separately. The electrolyte is continuously monitored and replenished.

Core Components of a Modern Industrial Electrolysis System

Electrolytic Cells

Durable, acid-resistant tanks (often PP, PVC, or lined steel) housing the anodes, cathodes, and electrolyte. Designed for continuous or batch operation.

Rectifier & Power Supply

Provides the precise, controlled DC current critical for efficient deposition and purity.

Cathode Starter Sheets/Blanks

High-purity surfaces where gold deposits.

Filtration System

Handles electrolyte purification and anode slime separation.

Ventilation & Scrubbing

Essential for safe handling of acid fumes (like HCl mist).

Control System

Monitors and regulates voltage, current density, temperature, and electrolyte composition for optimal commercial electrolytic gold refining.

Why Choose Electrolysis for Industrial Gold Refining? Key Benefits

Unmatched Purity

Achieves 99.99% (4N) or higher gold purity consistently, meeting LBMA and investment-grade standards. Essential for high purity gold production for banks and mints.

High Efficiency & Scalability

Processes large volumes of material continuously, ideal for refineries, mining operations, and large-scale recyclers. Significantly higher throughput than batch methods.

Effective Impurity Separation

Excellent removal of silver, PGMs, and base metals concentrated into recoverable anode slimes, maximizing overall metal value.

Reduced Chemical Consumption

Compared to purely chemical methods, electrolysis often uses less aggressive chemicals overall, primarily relying on electricity. The electrolyte is recycled.

Superior Process Control

Parameters like current density and temperature are precisely managed, ensuring consistent results crucial for industrial gold refining equipment.

Gold Electrolysis vs. Alternatives

Aqua Regia

Excellent for small batches/scrap but hazardous, generates NOx fumes, difficult to scale, and reclaiming PGMs is complex. Electrolysis is safer and more efficient for bulk.

Miller Process (Chlorination)

Faster for initial debasement but struggles to achieve consistent 99.99%+ purity; gold loss to slag can be higher. Electrolysis is the definitive final refining step.

Cupellation

Primarily for silver separation; not suitable for high-purity gold output.

Is a Gold Electrolysis System Right for Your Operation?

Consider this technology if you require:

Consistent production of 99.99%+ pure gold.

Processing significant volumes (kilograms to tonnes).

Maximizing recovery of PGMs from gold feed material.

A proven, controllable industrial process.

Turnkey gold purification systems for refinery setup or upgrade.

Invest in Purity, Invest in Efficiency

The gold electrolysis system is the undisputed cornerstone of modern, large-scale gold refining. It transforms crude bullion or doré into the pristine, high-value gold demanded by global markets.

Ready to explore industrial-grade electrolytic refining solutions? Contact us today to discuss your requirements for high-capacity gold refining plants and discover how our advanced systems can optimize your purity and profitability. Request a quote for your gold refinery project.