The Copper Refining Process: A Comprehensive Guide for Global Buyers

The copper refining process is a critical step in transforming raw copper into high-purity metal used in industries like electronics, construction, and renewable energy.

1. Smelting: The First Step in Copper Refining

Copper refining begins with smelting, where copper ore or concentrate is heated in a furnace to separate impurities. This stage produces blister copper (98–99% pure), which still contains sulfur, iron, and trace metals. While blister copper has some applications, it’s not suitable for high-demand sectors like electrical wiring or semiconductor manufacturing.

2. Fire Refining: Removing Sulfur and Impurities

Blister copper undergoes fire refining, a two-stage process:

Oxidation: Air is blown into the molten copper to oxidize sulfur and other impurities (e.g., lead, zinc). These form slag, which is removed.

Reduction: A reducing agent (e.g., hydrocarbons) is added to eliminate residual oxygen, producing fire-refined copper (99.5% purity).

This method is cost-effective but less efficient for removing noble metals like gold and silver.

3. Electrolytic Refining: Achieving 99.99% Purity

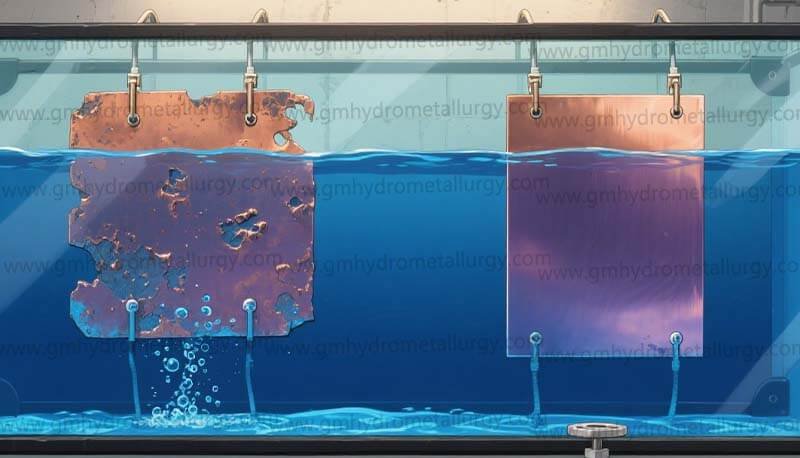

Electrolytic Refining Works

For applications requiring ultra-pure copper (e.g., power transmission, PCBs), electrolytic refining is essential. Here’s how it works:

1. Anode Casting

Fire-refined copper is cast into plates to serve as anodes.

2. Electrolysis

Anodes are immersed in an acidic copper sulfate solution. When electricity is applied, copper ions (Cu²⁺) dissolve from the anode and deposit onto copper cathodes, leaving impurities in the solution or as sludge.

3. Cathode Harvesting

Cathodes are removed, dried, and stored for shipment.

This process recovers valuable byproducts like silver and gold from anode slimes, enhancing profitability for refineries.

4. Modern Innovations in Copper Refining

Recent advancements, such as low-temperature refining, reduce energy consumption while maintaining efficiency. Additionally, wet refining methods are gaining traction for treating low-grade ores sustainably.

Why Understanding the Copper Refining Process Matter

For buyers, the copper refining process directly impacts product quality and cost. By partnering with refineries that prioritize advanced technologies like electrolytic refining, you secure materials that align with your project’s technical and sustainability goals.

Whether you’re sourcing for solar panels, transformers, or industrial machinery, mastering the copper refining process empowers informed decisions and builds trust with global suppliers.