Understanding Gold Refinery Machine Cost

Navigating the market for a gold refinery machine can be complex, with the gold refinery machine price varying widely. Your investment is crucial, impacting your operation’s efficiency, output purity, and long-term profitability.

What Determines the Cost of a Gold Refinery Machine?

Capacity and Throughput

Small-scale or jewelry refining machines for lower volume processing are naturally less expensive.

Industrial-grade gold refinery plants designed for high-volume, continuous operation command a higher price due to larger size, more robust components, and greater material handling capabilities.

Technology and Refining Process

Chemical-based systems may have a lower initial gold refining equipment price but involve ongoing chemical costs.

Advanced electrolytic refining systems offer higher purity (up to 99.99%) and better recovery rates. These systems, often preferred for high-volume commercial refining, represent a higher initial investment but lower long-term consumable costs and superior results.

Level of Automation

Manual or semi-automatic machines require more operator involvement and are priced lower.

Fully automatic gold refining machines integrate computerized controls, automated feeding, and casting. They maximize safety, consistency, and output, justifying a higher price for an automatic gold refiner.

Brand, Quality, and Manufacturer Support

Manufacturers like Guanma Machinery invest in R&D, superior materials (acid-resistant alloys), and precision engineering. This ensures durability, safety, and minimal gold loss.

The gold refinery machine price from a reliable manufacturer includes critical value-adds: comprehensive installation guidance, operator training, technical support, and warranty. Choosing a cheaper, unsupported option can lead to costly downtime and losses.

Customization and Additional Features

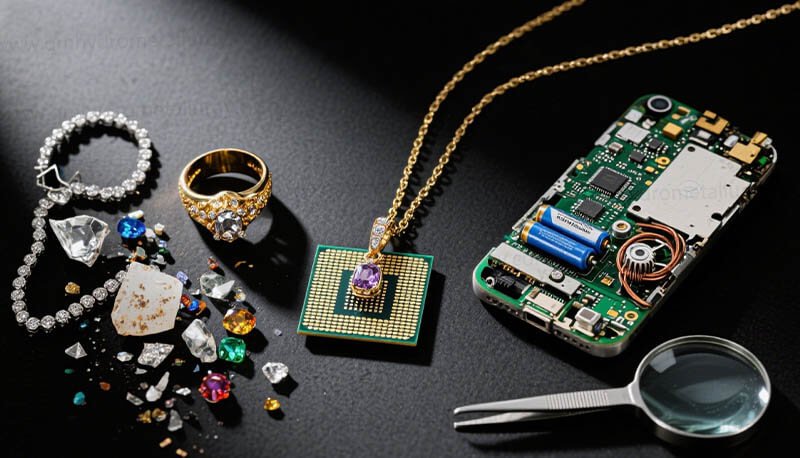

Requirements for precious metal recovery from e-waste or specific alloy processing need custom configurations.

Add-ons like integrated fume scrubbers (for environmental compliance), advanced filtration systems, or custom casting molds will affect the final industrial gold refining system cost.

Beyond the Price Tag: Calculating Your Return on Investment (ROI)

Gold Recovery Rate: A 1% higher recovery on a large volume pays for the machine rapidly.

Purity of Output: Higher purity gold (999.5+) fetches premium prices.

Operational Costs: Energy efficiency, chemical consumption, and labor requirements.

Uptime and Reliability: A robust machine from Guanma minimizes costly production halts.

How to Get an Accurate Gold Refinery Machine Quote

To receive a precise and competitive gold refinery machine price, be prepared to share:

Your expected daily/monthly processing volume.

The type of raw material (scrap jewelry, doré bars, electronic waste, etc.).

Desired final purity (e.g., 99.9%, 99.99%).

Preferred level of automation.

Any specific space or emission requirements.

Ready to Invest in a Reliable Gold Refining Solution?

The gold refinery machine price is your entry point to greater profitability and operational control.

Contact Guanma Machinery today for a detailed, no-obligation quotation tailored to your specific needs.