The lead electrolytic refining process is a critical technique for producing high-purity lead, essential for industries ranging from batteries to radiation shielding. If you’re sourcing refined lead products or planning to invest in refining technology, understanding this process can help you make informed decisions.

What Is the Lead Electrolytic Refining Process?

Electrolytic refining is an electrochemical method used to purify crude lead, often obtained from recycling or smelting operations. Unlike traditional fire refining, which relies on thermal treatment, electrolysis achieves significantly higher purity levels—up to 99.99% pure lead. This makes it the preferred method for applications requiring ultra-pure lead.

How Does It Work?

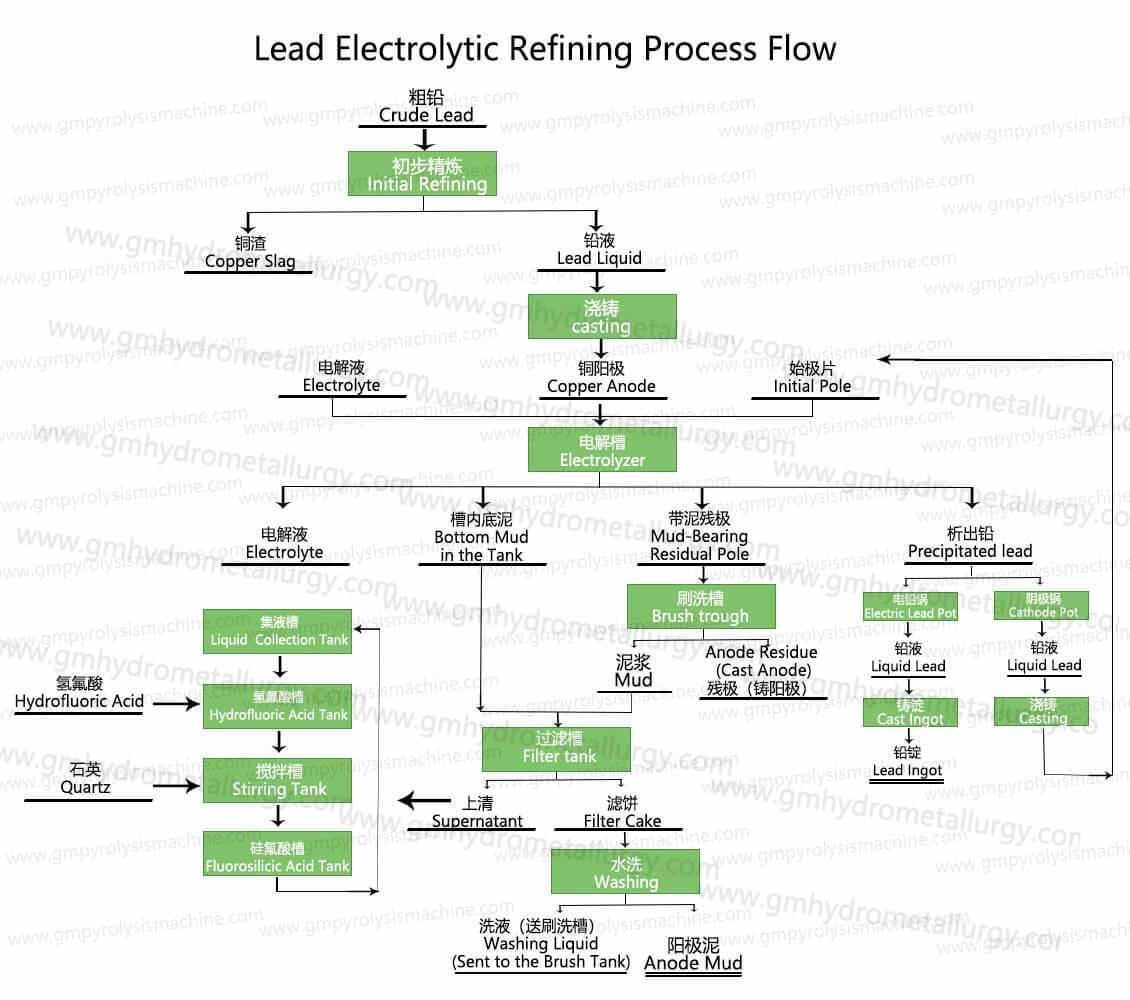

The process involves immersing an anode (impure lead) and a cathode (pure lead starter sheet) in an electrolytic solution, typically fluosilicate-based. When direct current is applied, lead ions migrate from the anode to the cathode, depositing as pure metal. Impurities, including precious metals like silver and bismuth, settle as anode slime, which can be recovered and processed separately.

Key Advantages of Electrolytic Refining

1. Exceptional Purity

Achieves 99.99% purity, meeting stringent industry standards.

2. Efficiency

Minimizes lead loss and maximizes metal recovery.

3. Environmental Benefits

Reduced emissions compared to pyrometallurgical methods.

4. By-Product Recovery

Precious metals collected from anode slime add economic value.

Applications of High-Purity Lead

Electrolytically refined lead is ideal for:

Advanced lead-acid batteries

Radiation shielding in healthcare and nuclear industries

Corrosion-resistant coatings and alloys

Choosing a Reliable Supplier

When sourcing electrolytically refined lead or related equipment, consider:

Technology Expertise

Suppliers should use modern, automated systems for consistent quality.

Certifications

Ensure compliance with international standards.

Customization

Ability to provide tailored solutions for specific purity or form requirements.

The lead electrolytic refining process is indispensable for producing premium-grade lead with minimal environmental impact. By partnering with experienced suppliers and leveraging advanced technology, businesses can secure a sustainable source of high-purity lead for diverse industrial applications.

For more information on electrolytic refining solutions, contact our experts today!