Hydrometallurgy battery recycling is revolutionizing how we recover critical metals from spent lithium-ion, NiMH, and lead-acid batteries. Facing low metal recovery, environmental compliance headaches, or inefficient pyrometallurgical methods? Discover why leading recyclers globally are switching to hydrometallurgical solutions for higher purity, lower costs, and true circularity.

Why Hydrometallurgy Outperforms Traditional Battery Recycling?

While pyrometallurgy burns batteries at high temperatures (losing lithium, aluminum, and electrolyte), hydrometallurgy uses precise aqueous chemistry to dissolve and selectively extract metals. The result?

95%+ Recovery Rates for Li, Co, Ni, Mn vs. <50% for lithium in smelting

Battery-Grade Purity (99.9%) suitable for direct cathode re-manufacturing

Lower Energy Consumption & Emission (50-70% less CO2 than pyromet)

Economic Processing of Black Mass from diverse battery chemistries (NMC, LFP, LCO)

The Science-Driven Hydrometallurgy Battery Recycling Process

Modern hydrometallurgy integrates:

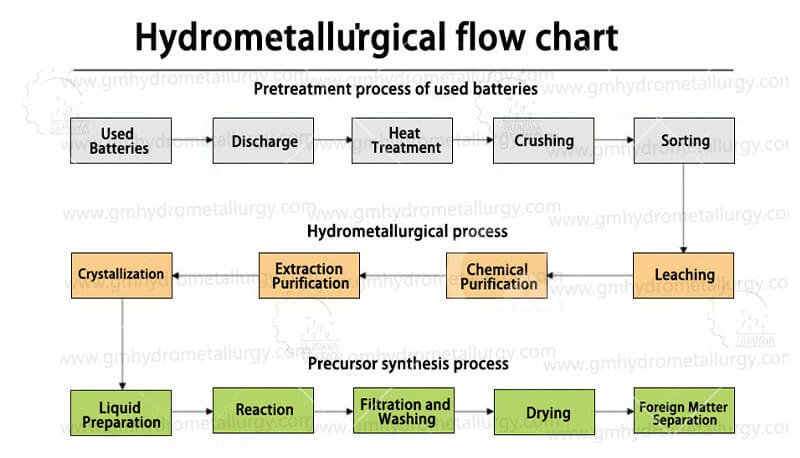

1. Precision Pre-Treatment

Automated discharge & dismantling

Cryogenic or mechanical shredding

Advanced separation (screening, air classification, flotation) to isolate high-value black mass.

2. Selective Leaching

Acid Leaching (H₂SO₄, HCl): Optimized concentration/temperature to dissolve target metals

Bio-Leaching: Eco-friendly alternative using microorganisms

Redox-Mediated Leaching: Enhances lithium extraction from LFP batteries

3. Multi-Stage Purification

Solvent Extraction (SX): Selective separation of Co, Ni, Mn using tailored extractants

Ion Exchange (IX): High-precision removal of impurities (Al, Cu, Fe)

Precipitation: Controlled pH adjustment to recover lithium carbonate/phosphate

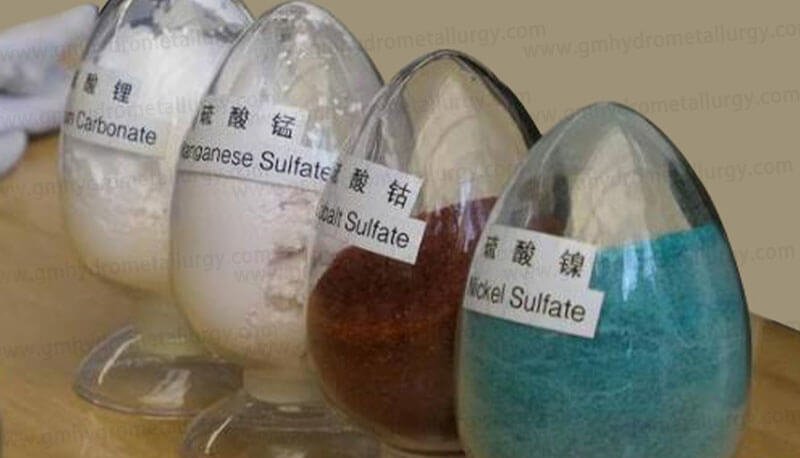

4. High-Purity Product Synthesis

Crystallization: Producing battery-grade Li₂CO₃/Li₃PO₄

Electrowinning: Direct recovery of cobalt/nickel metals

Precursor Synthesis: Directly formulating NMC/NCA precursors for cathode plants

Tangible Benefits Driving Industry Adoption

Profitability Boost: Recover 3X more lithium from LFP batteries vs. pyromet.

Zero Waste Operations: Full electrolyte recovery & gypsum/iron residue valorization.

Modular Scalability: From pilot plants (1 ton/day) to industrial hubs (100+ tons/day).

Lower OPEX: Reduced reductant/energy needs vs. smelting.

Applications Across the Battery Ecosystem

EV Battery Gigafactories: Closed-loop material sourcing.

E-Waste Recyclers: Maximizing value from portable electronics.

Energy Storage Systems: Sustainable EOL management for grid-scale BESS.

Mining Companies: Secondary refining of production scrap.

Battery Manufacturers: Pre-consumer scrap valorization.