Silver Recovery from Solar Panel Silicon Cells

Silver Recovery from Solar Panel Silicon Cells is our eco-efficient process designed to extract high-purity silver from end-of-life or defective crystalline silicon (c-Si) photovoltaic panels.

Photovoltaic (PV) panels, also known as solar panels, are primarily composed of silicon cell, glass, EVA (ethylene-vinyl acetate copolymer), TPT back sheets, and aluminum frames. The silver exists mainly as silver paste between the silicon wafers and electrodes.

Raw materials & Final Products

Raw materials: Silver-containing silicon wafers/silicon powder, with silver paste attached to the surface (the main components are silver powder, glass powder, and organic adhesive). The silver content usually accounts for 0.5%~1.2% of the weight of the silicon wafer.

Final Products: High-Purity Silver Ingots/Sterling Silver Ingots (usually 99.99% pure silver).

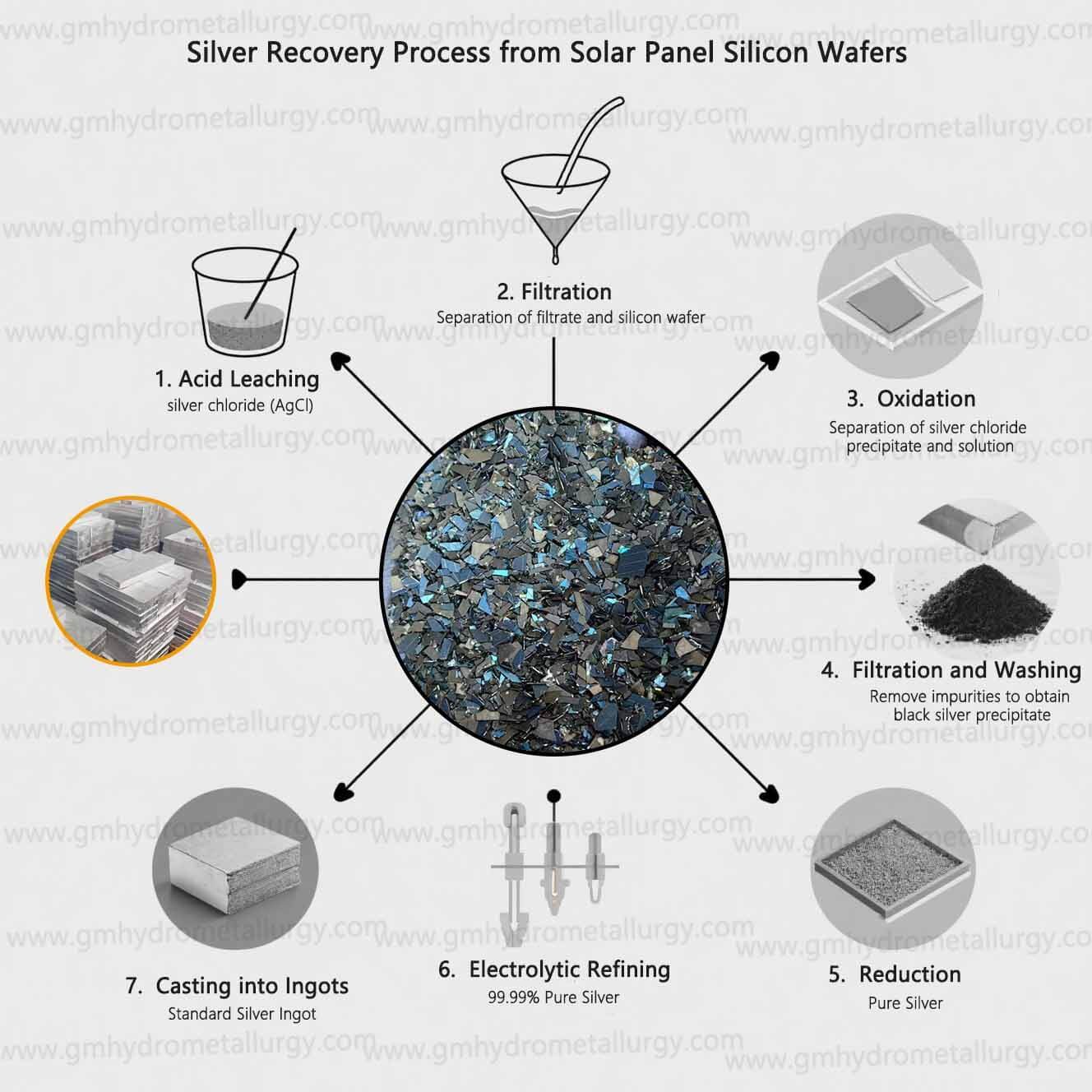

Silver Recovery Process from Solar Panel Silicon Wafers

To efficiently recover these valuable resources, Guanma Machinery adheres to a green and environmentally friendly recycling philosophy, offering high-efficiency solutions for extracting precious metals from e-waste. Below are detailed introductions to several common solutions and their key equipment:

1. Acid Leaching

Prepared silicon wafers/powder are added to a suitable acid solution and stirred. The purpose is to dissolve the silver paste from the silicon, forming silver chloride (AgCl).

2. Filtration

The leached mixture is filtered to separate the silver chloride-containing filtrate from the silicon wafers/powder. The filtrate contains silver ions, while the silicon powder is the primary solid waste for further processing.

3. Oxidation

Silver chloride (AgCl) in the filtrate is oxidized to form a precipitate. After oxidation, the silver chloride precipitate separates from the solution as a solid.

4. Filtration and Washing

The oxidized precipitate is filtered and washed to remove impurities. The resulting precipitate is primarily silver, appearing as a dark-colored solid.

5. Reduction

The washed silver precipitate undergoes reduction to yield pure silver.

The reduced silver is dried to remove moisture. The dried silver is then electrolyzed to obtain 99.99% pure silver.

7. Casting into Ingots

The electrolytic silver is granulated and cast into standard pure silver ingots.

Key Features & Benefits

Maximize Resource Value

Expertly recover >95% of high-purity silver (up to 99.95%) from PV silicon wafers, turning waste into significant revenue.

Advanced & Selective Extraction

Utilizes optimized chemical processes (nitric acid-based or alternative eco-conscious leaching systems) to efficiently dissolve and isolate silver from silicon, glass, and other metals like tin/lead.

Environmentally Responsible

Compliant closed-loop system minimizes chemical consumption, neutralizes emissions, and ensures safe residue disposal. Supports the circular economy for solar.

High-Purity Output

Integrated purification and refining (electrolysis or chemical reduction) deliver silver suitable for reuse in electronics, new PV cells, jewelry, or investment.

Cost-Effective Recycling

Reduces reliance on primary silver mining and lowers processing costs compared to conventional methods. Ideal for PV recyclers and refiners.

Why Choose Guanma Machinery Silver Recovery Solution?

Guanma Machinery provide efficient and scalable silver recovery from solar panel silicon wafers, transforming PV recycling from an environmental cost into a strategic resource recovery operation. Our proven technology ensures maximum yield, operational safety, and adherence to global environmental standards.

Discover how our sustainable silver extraction unlocks value from your PV waste stream. Contact Guanma Machinery today for a consultation.

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)