Regeneration and Recovery of Platinum and Silver from Waste Residues

Source of Platinum- and Silver-Bearing Waste Residues

During the production of platinum-based drugs (cisplatin and carboplatin), waste residues containing 5%~8% platinum (Pt) as silver iodide (AgI) are generated. The platinum exists in a finely dispersed particle state within the silver iodide.

Previous Method and its Drawbacks

The nitric acid dissolution method was previously used to separate and recover platinum and silver. However, this method causes platinum dispersion: during nitric acid dissolution, about 20% of the Pt co-dissolves with Ag. Subsequently, when precipitating AgCl from the nitric acid solution using HCl or NaCl, part of the platinum co-precipitates with AgCl in the form of Ag₂PtCl₆. This dispersion of Pt and the multiple separation steps required for Ag and Pt result in a long process flow and a low direct recovery rate for Pt.

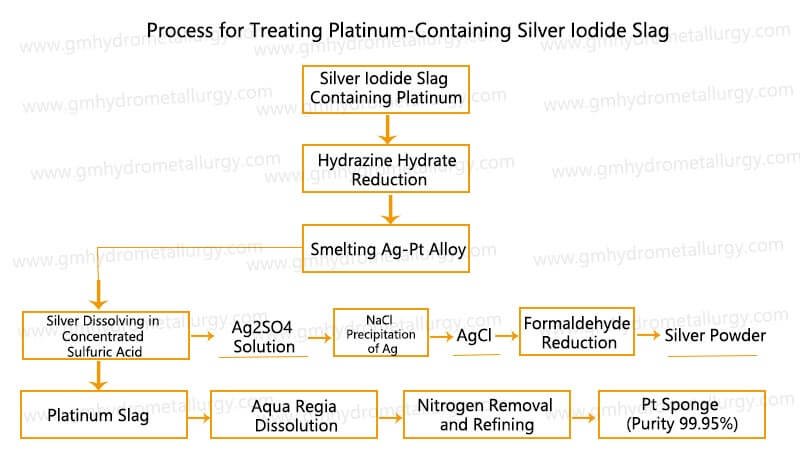

Regeneration and Recovery of Platinum and Silver from Waste Residues Process

Hydrazine Hydrate Reduction: This step is carried out at 90°C under stirring conditions to convert Pt and Ag compounds into their metallic states. The reactions are:

2Pt(NH₃)I₂ + N₂H₄·H₂O + 4NaOH = 2Pt + 4NaI + N₂ + 5H₂O + 2NH₃

4AgI + N₂H₄·H₂O + 4NaOH = 4Ag + 4NaI + N₂ + 5H₂O

After washing with water and drying, a powdered metal mixture is obtained, containing Pt 8.16%, Ag 83.1%, and the remainder being AgI. Experiments proved that directly dissolving this Ag-Pt mixed powder in concentrated sulfuric acid results in a low Ag dissolution rate.

Smelting to Alloy: If the mixed powder is blended with a small amount of soda ash (Na₂CO₃) and borax (Na₂B₄O₇) and smelted at 1300°C, an Ag-Pt alloy is formed (containing Pt 9.14% and Ag 90.64%).

Alloy Dissolution and Silver Recovery: The flaky alloy is directly dissolved in concentrated sulfuric acid by heating to 150°C for 3 hours. The Ag dissolution rate reaches 99.51%. Silver is precipitated from the solution as AgCl using NaCl. While in a suspended state, the AgCl is reduced to silver powder using formaldehyde, silver recovery rate: >99%.

The insoluble residue contains Pt 93.88% and Ag 4.57%. This residue is dissolved in aqua regia. Following nitric acid removal (denitration), the solution is refined to yield pure platinum product.Platinum recovery rate: 99.5%, This process is applicable to the treatment of other silver-platinum waste materials.

Caution: The formaldehyde reduction process involves intense exothermic heat release, which can cause violent splattering. Strict control of the reduction speed is essential.

If you are planning to start a precious metal platinum recycling business, Guanma Machinery precious metal recycling equipment supplier will provide you with solutions. Contact us now to get customized solutions and quotes!

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)