Silver Refining Machine: During the separation and refining of platinum group metals (PGMs) concentrates, a significant portion of silver is produced as AgCl (silver chloride) residues. Depending on the nature and composition of the raw materials, chemical or electrolytic refining methods can be employed. The chemical method is suitable for small-scale processing of impure silver chloride compounds, while the electrolytic method is more efficient for large-scale refining of crude silver.

FEATURES:

Capacity: Coarse silver color ≥ 90%; silver electrolysis capacity 300-3,000t/a, meeting the requirements of large-scale production.

Electrolytic silver powder: Purity of silver powder ≥99.99%.

Temperature control: Temperature of conductive bar and lug ≤ 70°C and temperature of electrolyte≤50°℃ to ensure the safety and stability of electrolysis.

Operation frequency: Replace a batch of plates every day (can be set according to specific process requirements) to ensure electrolytic efficiency and good electrolyzer condition.

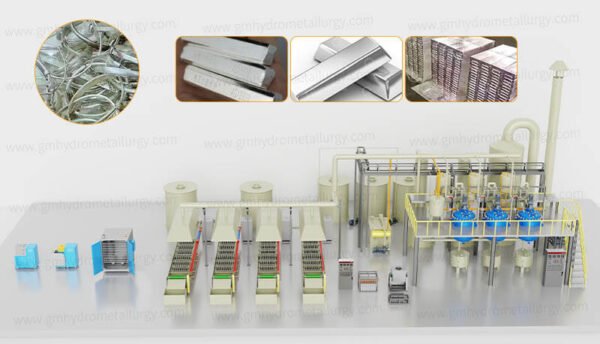

Silver Refining Process Flow

Silver electrolytic refining typically involves several key steps: anode processing, starter sheet production, electrolysis, electrolyte purification, and anode slime treatment. The main process flow is as follows:

1. Preparation of Electrolyte

The process of preparing silver nitrate electrolyte is termed solution preparation. High-purity silver powder (99.99%) is dissolved in nitric acid until fully reacted. The insoluble residues are filtered out, and the resulting solution is transferred to the electrolytic cell.

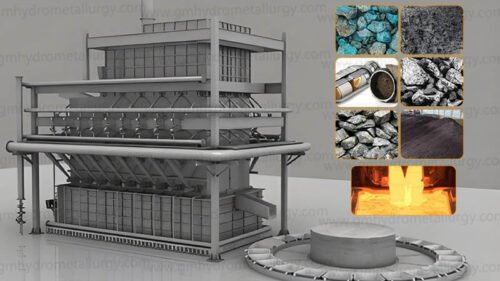

2. Anode Plate Casting

Raw materials with a silver content exceeding 92% are melted and cast into anode plates using a medium-frequency furnace. These plates are then mounted in designated positions within the electrolytic cell.

3. Electrolysis and Cell Discharge

Electrolysis is conducted using a silver electrolytic refining machine, involving three stages: electrolysis, silver powder scraping, and cell discharge. The extracted silver powder is washed thoroughly. After electrolysis, the discharge valve is opened to collect the silver powder, which is subsequently washed, dried, and cast into silver ingots.

4. Ingot Casting and Marking

The dried silver powder is sent to the ingot casting and marking stage. Finalized ingots are labeled and stored in inventory.

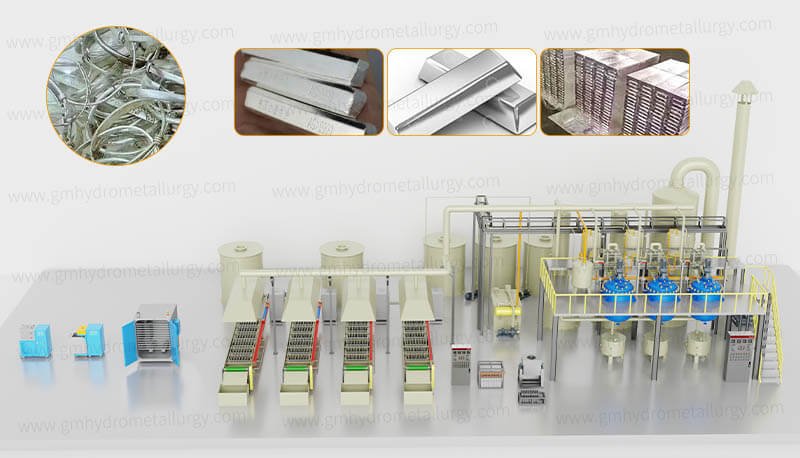

Raw Material&Final Product

Silver Jewelry High Purity

The raw materials for silver electrolytic refining mainly include the following: gold-silver alloy (gold-silver alloy with a silver content of more than 90% obtained by processing copper and lead anode mud), silver-containing waste (crude silver obtained by processing other silver-containing waste), silver powder (pure silver powder or silver powder with a high silver content can also be used as raw materials)

Equipment Advantages

Advantages of Silver Refining Systems

1. High-Current-Density Electrolysis Technology

Utilizes advanced electrolysis with a cathode current density of 750 A/m², significantly boosting production efficiency.

2. Stable Product Quality

Consistently delivers electrolytic silver powder with >99.99% purity, ensuring premium-grade output.

3. Electrolyte Cooling System

Integrated cooling mechanism minimizes electrolyte evaporation, maintaining process stability and reducing operational costs.

4. Exhaust Gas Condensation System

Effectively cools exhaust gases to prevent silver loss, enhancing metal recovery rates.

5. PLC Remote Control & Real-Time Data Monitoring

Automated operation via PLC remote control paired with a precision data monitoring system for seamless process management.

6. Eco-Friendly Exhaust Treatment

Advanced exhaust gas treatment system ensures emissions comply with strict environmental regulations.

Supporting Equipment

Silver Vacuum Ingot Casting Machine

Silver vacuum ingot casting machine features: can customize gold beans, gold nuggets, and silver nuggets of different shapes and weights; suitable for precious metals such as gold/K gold/silver; PLC control system, easy operation, smart screen; vacuum ingot casting.

Sliver Vacuum Continuous Casting Machine

Sliver Vacuum Continuous Casting Machine: Temperature max.1500C above; Cast strip, plate, tube, multiple strips, customized; Good color, high density, no porosity, no oxidation; Electromagnetic stirring function, no color segregation.

Silver Powder Cleaning Drying System

Capacity: 400kg/2h Drying effect: Molsture content of silver powder after treatment ≤ 3%, ensuring that the product reaches the ideal dry state. Fully automatic: The equipment runs automatically without manual intervention to improve production efficiency. Eco-friendly operation: No flue gas is produced at the operation site, meeting the environmental protection requirements.

Silver Vacuum Granulator Machine

Silver Vacuum Granulator Machine: mechanical stirring function to make the product more uniform; secondary feeding can be performed under vacuum to ensure that the metal is fully melted; equipped with a water-locking device to isolate excess moisture and make it easier to take out materials;

If you want to start silver electrolysis refining business, please contact Guanma Machinery for solutions and quotations!

Technical Parameter

Silver Electrolytic Refining Machine Technical Parameters

If you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity kg/day | Power/kw | Size(Length*Width*Height) |

| SER-20 | 20kg | 5 | 1500*700*1850 |

| SER-50 | 20-50kg | 10 | 1600*800*1900 |

| SER-100 | 50-100kg | 15 | 570*840*1200 |

| SER-200 | 100-200kg | 25 | 1200*840*1300 |

| SER-300 | 200-300kg | 39 | 1930*840*1300 |

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)