Precious metal electrolysis recovery equipment Manufacturers produce gold silver copper palladium platinum rhodium recovery machines with broad applications. These systems can:

Recover gold, silver, platinum, rhodium, and palladium from electroplating wastewater.

Extract gold, silver, platinum, rhodium, and palladium from electroplating rinse tank wastewater.

Recover gold and silver from circuit board gold etching solutions.

Extract gold and silver from electronic waste stripping solutions or leachates.

Recover silver from fixer solutions (photographic developer waste).

Extract gold or silver from steel strip solutions.

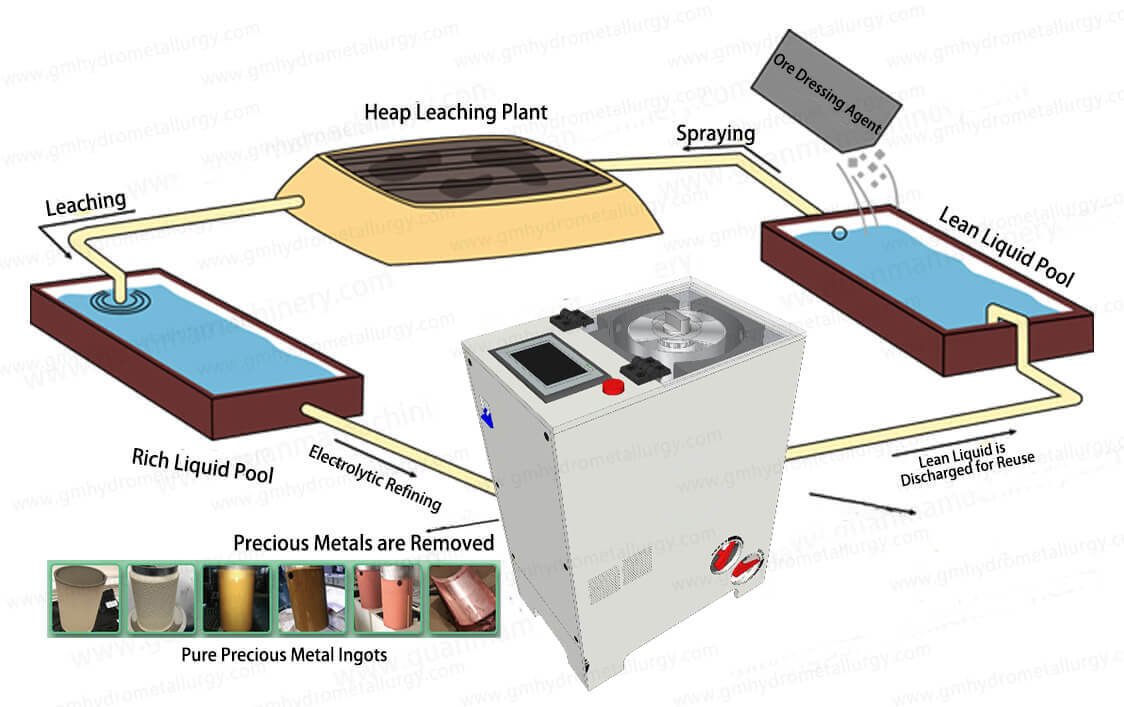

Precious Metal Electrolysis Recover Process Flow

1. After installation, the equipment waits for the film output machine to drain liquid into its storage tank.

2. Once the storage tank reaches the preset water level, the water inlet pump is activated to transfer the liquid to the electrolysis tank for electrolysis.

3. After electrolysis, the processed wastewater is automatically discharged.

4. The system then refills the storage tank to the preset level and pumps liquid into the electrolysis tank again.

5. If the storage tank level is insufficient, the equipment pauses and resumes operation once the preset level is reached.

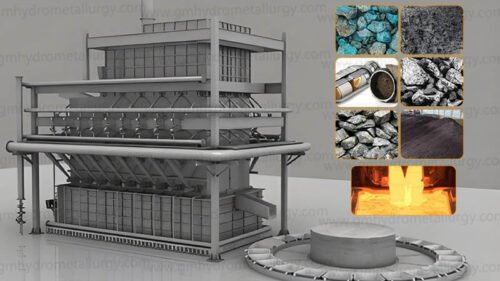

Raw Material&Final Product

Copper Ore

CPU

Electroplating Wastewater

Gold Electrolytic

Silver Electrolytic

Electrolytic Silver

Electrolytic Copper

The precious metal electrolysis recovery equipment recovers gold, silver, copper, platinum, rhodium, palladium, and other precious metals from: Electroplating wastewater, Circuit board gold etching solutions, Electronic waste materials, Electronic scrap stripping solutions, Waste photographic fixer solutions, Activated carbon desorption solutions from gold mines, Copper ores. It achieves a recovery rate exceeding 99% and directly extracts metals with purities of 95% to 99.8%.

Equipment Advantages

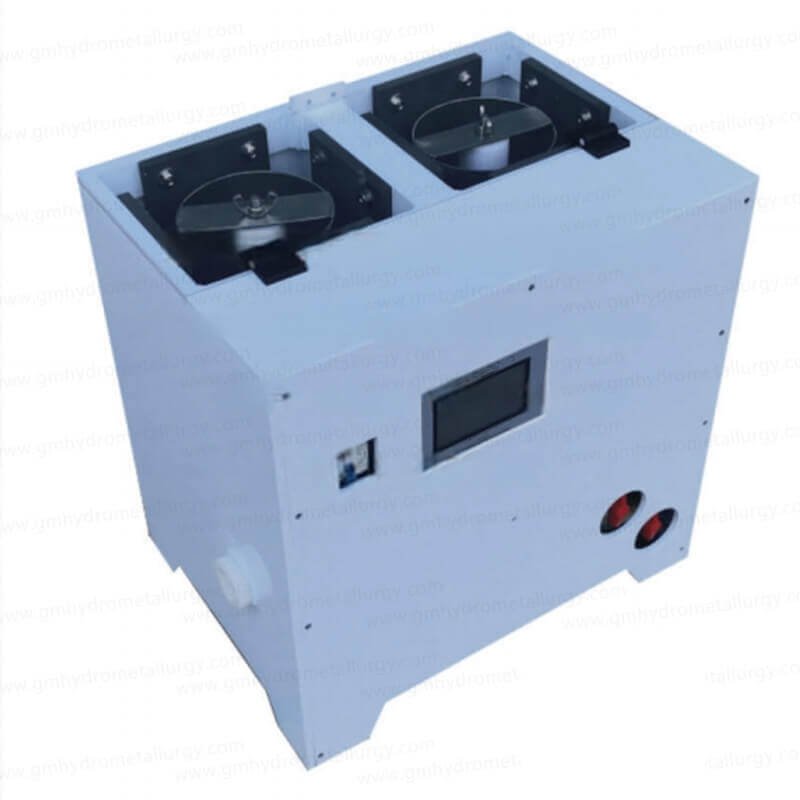

1. Simple Process

Compact footprint, low power consumption, simple process, and portability.

2. High Recovery Rate

Recovery rate >99%, yielding metals with purities of 95% to 99.8%.

3. High Automation

User-friendly operation, high automation, and no need for dedicated supervision.

4. Customizable Production Line

Customizable fully automated production lines for efficient gold, silver, copper, and other precious metal recovery.

5. Electrolysis Technology

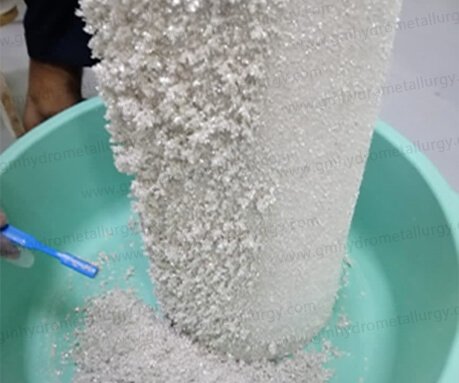

Utilizes rotating cathodes and high-frequency pulse intelligent electrolysis technology to recover gold and other metals without consumables or electrolytic accelerators—only minimal electricity consumption.

6. Electrolytic Adsorption Principle

Operates on the principle of electrolytic adsorption, converting metal ions in liquids into metallic form adsorbed onto the cathode. The accumulated metal is then peeled off as residue for further refining or direct use.

Technical Parameter

Precious Metal Electrolytic Recovery Equipment Technical Parameters

| Model | Treatment water | Power | Size(Length*Width*Height) | |

| GM-60 |

|

60-80L/Day | 300W | 600*450*600mm |

| GM-200 |

|

100-200L/Day | 300W | 300*450*600mm |

| GM-400 |

|

200-500L/Day | 350W | 600*450*600mm |

| GM-600 |

|

300-800L/Day | 400W | 900*450*600mm |

| GM-800 |

|

500-1000L/Day | 500W | 1200*450*600mm |

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)