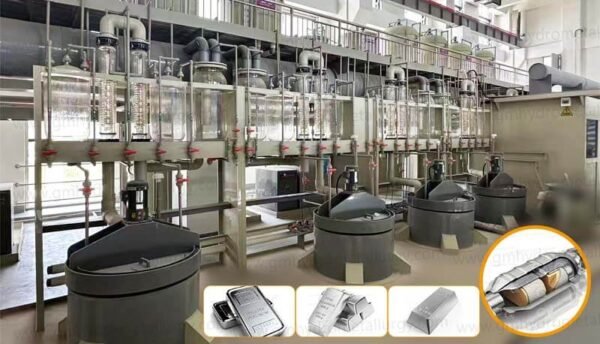

Platinum Palladium Rhodium Refining Equipment

Why invest in specialized platinum palladium rhodium refining equipment? These Platinum Group Metals (PGMs) are incredibly valuable but notoriously difficult and hazardous to separate and purify from complex feed materials. Efficient, safe, and high-yield refining is critical for profitability and environmental compliance. Our industry-leading PGM refining machinery is engineered to solve these exact challenges, transforming your scrap and waste into high-purity, investment-grade metal.

Platinum Palladium Rhodium Refining Methods

Platinum Refining

Among the platinum group metals (PGMs), platinum refining boasts the most mature technology. The refining process seamlessly integrates with PGM separation. Feed materials can include crude platinum (>90% assay), platinum-bearing solutions, or stripped solutions from solvent extraction. Key refining methods are the Ammonium Chloride Repeated Precipitation method and the Oxidative Hydrolysis method.

Palladium Refining

The refining process typically connects directly to the separation stage. Feed materials include crude palladium (>90% Pd), palladium chloro-complex acid solutions, or ammonia stripping solutions from solvent extraction. Primary refining methods are the Ammonium Chloropalladate Precipitation method and the Ammonia Complexation Combined Process.

Rhodium Refining

Rhodium refining methods primarily rely on modifying ligands to form specific complexes with distinct properties, states, or structures, enabling separation from other precious and base metal impurities. The process involves two stages: purification of rhodium compounds and production of pure metal. All rhodium refining occurs in solution, requiring initial dissolution of the crude metal.

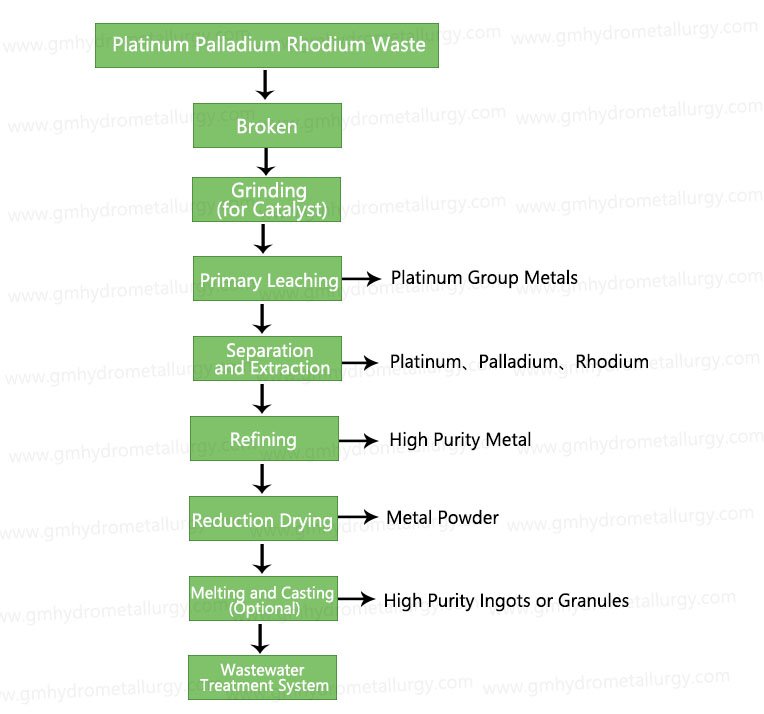

Platinum Palladium Rhodium Refining Equipment Process Flow

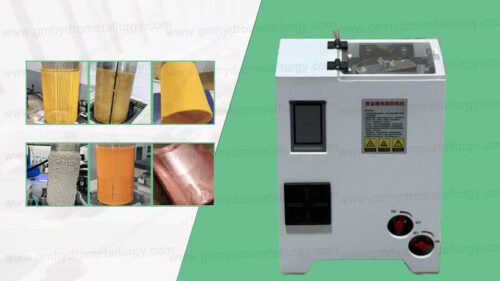

1. Feed Preparation & Analysis

Crushing, Milling (for catalysts), Sampling & Assaying to determine optimal process parameters.

2. Primary Leaching

Selective dissolution of base metals and initial PGM extraction using optimized chemical solutions within our platinum recovery equipment.

3. PGM Separation & Concentration

Advanced techniques including selective precipitation and solvent extraction for PGMs to isolate Pt, Pd, and Rh fractions.

4. Purification

Multiple stage refining (re-precipitation, ion exchange) to achieve ultra-high purity levels for each individual metal.

5. Reduction & Drying

Conversion of purified salts to metal powder or sponge using chemical reduction or thermal methods within our rhodium refining plant.

6. Melting & Casting (Optional)

Production of high-purity ingots or granules using induction melting furnaces.

7. Effluent & Residue Treatment

Integrated closed-loop wastewater treatment system for PGM recovery and environmental compliance. Safe handling and disposal of inert residues.

Raw Material&Final Product

Catalysts

Jewelry Scrap

Mining Concentrates

Industrial Catalysts

Rhodium

Our Platinum Palladium Rhodium Refining Equipment expertly process:

Spent Automotive Catalytic Converters (Ceramic & Metallic), Jewelry Manufacturing Scrap & Sweeps, Industrial Catalysts (Chemical, Petrochemical), Electronic Waste (PCBs, Components), Dental & Medical Scrap, Mining Concentrates & Tailings, PGM-Laboratory Residues.

Platinum (Pt): ≥ 99.95% Pure

Palladium (Pd): ≥ 99.95% Pure

Rhodium (Rh): ≥ 99.90% Pure

Ready for resale to refineries, bullion markets, or industrial users.

Equipment Advantages

Why Choose Guanma Machinery Platinum Palladium Rhodium Refining Equipment?

Unmatched Recovery Rates

Patented chemistry and process control maximize your yield and profitability from valuable PGMs, Recovery Rate >98% for Pt, Pd, Rh (depending on feedstock).

Industry-Leading Purity

Consistently produce metals meeting industry-specific standards.

Environmental Responsibility

Closed-loop design minimizes waste, effluent, and emissions. Compliant with international environmental regulations

Operational Efficiency

Advanced automation reduces labor costs, improves process consistency, and minimizes human error. Semi-automatic and fully automatic options available.

Robust & Durable

Built with corrosion-resistant materials for long service life in demanding chemical environments.

Scalable & Customizable

Solutions tailored to your specific feedstock volume, composition, and desired output.

Comprehensive Support

From feasibility studies and plant design to installation, training, and ongoing technical support.

Stop Losing Valuable Platinum, Palladium & Rhodium!

Inefficient refining means lost revenue and potential environmental liability. Guanma Machinery is a leading precious metal refining equipment manufacturer, We provide end-to-end solutions, not just machines.

Ready to Optimize Your PGM Refining Operations? Contact Guanma Machinery Today! Get a custom solution and price for your needs.

Technical Parameter

Platinum Palladium Rhodium Refining Equipment Technical Parameters

If you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Capacity | Customizable(Typical Range: 100kg - 5000kg input material per batch/day) |

| Recovery Rate | >98% for Pt, Pd, Rh (depending on feedstock) |

| Purity Output | Pt ≥ 99.95%, Pd ≥ 99.95%, Rh ≥ 99.90% |

| Process Method | Integrated Hydrometallurgical (Leaching, Precipitation, Solvent Extraction) & Pyrometallurgical (Calcination, Smelting - Optional) |

| Automation | Level Semi-Automatic or Fully Automatic Control Systems |

| Safety Systems | Advanced Fume Scrubbing (Wet & Dry), Explosion-Proof Design, Automated Process Monitoring & Alarms |

| Footprint | Modular Design, Optimized for Efficient Use of Space |

| Utility Requirements | Tailored (Power, Water, Process Gases, Chemicals) |

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)