Guanma Machinery PGM Refining Equipment optimizes platinum group metals recovery, whether processing scrap automotive catalysts, electronic waste, jewelry alloys, mine concentrates, or chemical residues. With soaring global demand and declining ore grades, investing in advanced precious metal recovery technology is crucial for securing your supply chain security and maximizing returns from complex secondary materials.

Platinum Group Metals (PGMs), also known as Platinum Group Elements (PGEs), are rare and valuable, making their recovery historically important.

PGM refining refers to the process of removing impurities from crude PGM feed materials to produce pure metals or pure compounds.

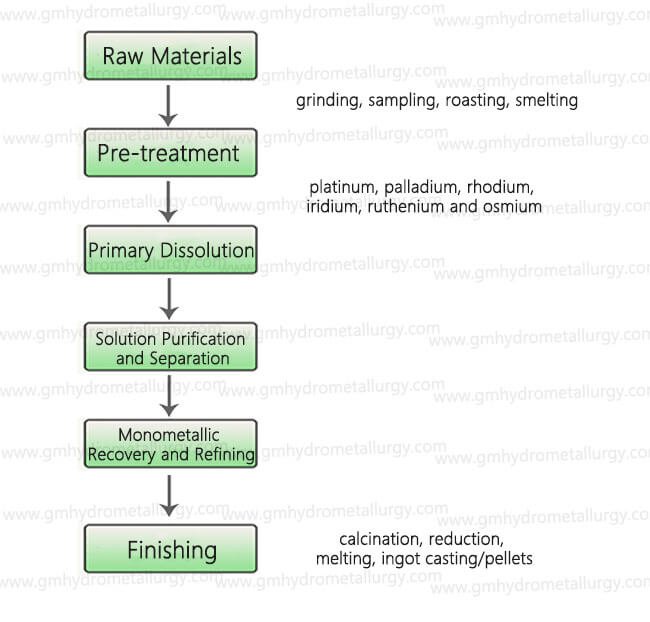

Oxygen Enriched Side-Blown Furnace Process Flow

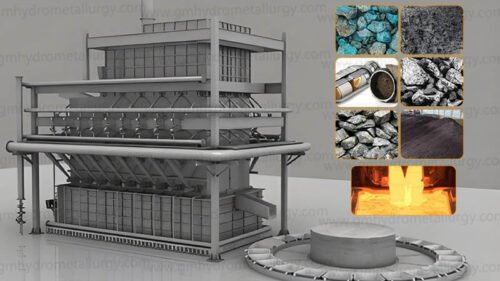

1. Pyrometallurgical Smelting

Pyrometallurgical Smelting: Includes slagging, collection, separation of base metals, and integrated environmental protection equipment.

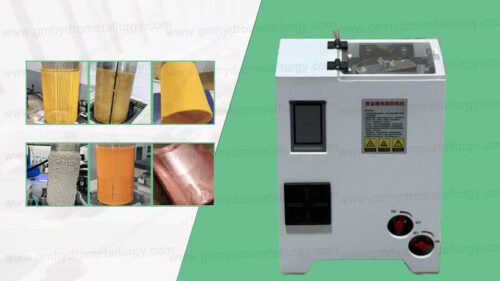

2. Hydrometallurgical Leaching & Refining

Hydrometallurgical Leaching & Refining: Involves acid leaching, precipitation, filtration, reduction, solvent extraction, and other processes to isolate and purify the precious metals.

1: Pre-Treatment & Conditioning

Milling, sampling, roasting (organics removal), smelting (concentrate formation).

2: Primary Dissolution

Targeted leaching (Aqua Regia, HCl/Cl2, HCl/O2, Sulfuric Acid pressure leaching) optimized for specific feed and PGMs.

3: Solution Purification & Separation

Solvent Extraction (SX): Highly selective separation of Pt, Pd, Rh, Ir using proprietary reagents. Key for complex streams.

Ion Exchange (IX): Fine purification, especially for Rh, Ir, Ru, Os removal from base metals.

Precipitation/Cementation: Initial concentration or removal of impurities (e.g., gold, silver, base metals).

4: Individual Metal Recovery & Refining

Ammonium Salt Precipitation: Classic method for high-purity Pt & Pd (e.g., Ammonium Hexachloroplatinate).

Selective Reduction: Controlled precipitation of pure metal powders (e.g., Hydrazine for Pd).

Electrowinning: Direct recovery of pure metal cathodes from purified solutions.

Crystallization: For high-purity salts (e.g., Rhodium Chloride, Iridium Chloride).

5: Finishing

Calcination, reduction (H2), melting, and casting into ingots/granules.

Raw Material & Output

Applicable Raw Materials: Scrap automotive three-way catalysts, spent petroleum catalysts, industrial catalysts, electronic waste (e-waste), anode slimes, alloy scrap, ores (copper ore, lead-zinc ore, gold ore, etc.), and other PGM-bearing materials.

Final Products: High-purity Platinum (Pt), Palladium (Pd), Rhodium (Rh), Iridium (Ir), Ruthenium (Ru), and Osmium (Os) metals meeting industry standards, with recovery rates ≥99% and purity levels reaching 99.995% or higher.

Equipment Advantages

Guanma Machinery PGM Refining Machine Advantages

PGM recovery rates ≥99%

Maximized Profitability: Industry-leading PGM recovery rates (≥99%) directly translate to higher revenue from your valuable scrap and concentrates.

Operational Cost Efficiency

Advanced process optimization minimizes consumption of acids, reagents, and energy. Integrated precious metal recovery plant design reduces labor requirements.

Environmental Compliance

Built-in emission control systems and zero liquid discharge or advanced wastewater treatment ensure adherence to strictest international regulations.

Modularity & Scalability

Design allows for phased investment and future capacity expansion. Easily adapts to changing feedstock volumes or types.

PLC Control

PLC system ensures precise control, optimal performance, real-time monitoring, data recording, and remote diagnostics for minimal downtime.

Guanma Machinery - Platinum Group Metals Refining Equipment Manufacturer

We provide complete, integrated solutions capable of transforming complex PGM-bearing materials into high-purity, high-value products. Our systems are custom-engineered precisely for your unique feedstock and capacity requirements.

Ready to maximize your PGM recovery profitability and ensure sustainable operations?

Contact us today for a detailed technical consultation and a customized quotation for your specific Platinum Group Metals Refining project!

Technical Parameter

PGM Refining Equipment Technical Parameters

| Processing Capacity | 0.1~5ton/day (customizable) |

| Recovery Rate | ≥99% |

| Final Purity Metal Purity | ≥99.995% |

| Process Method | Hydrometallurgy and pyrometallurgy (customizable according to raw material requirements) |

| Automation level | PLC control system |

| Emissions | Waste gas and wastewater treatment system, in line with environmental protection requirements |

| Customized According to Raw Materials and Production Capacity Requirements | |

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)