LFP Battery Black Mass Hydrometallurgical Recycling Machine: Among the recycling technologies for spent LFP batteries—hydrometallurgy, pyrometallurgy (dry process), and bio-recovery—hydrometallurgy is the most effective method. It specifically targets the recovery of key elements such as Al, Fe, and Li from spent LFP batteries.

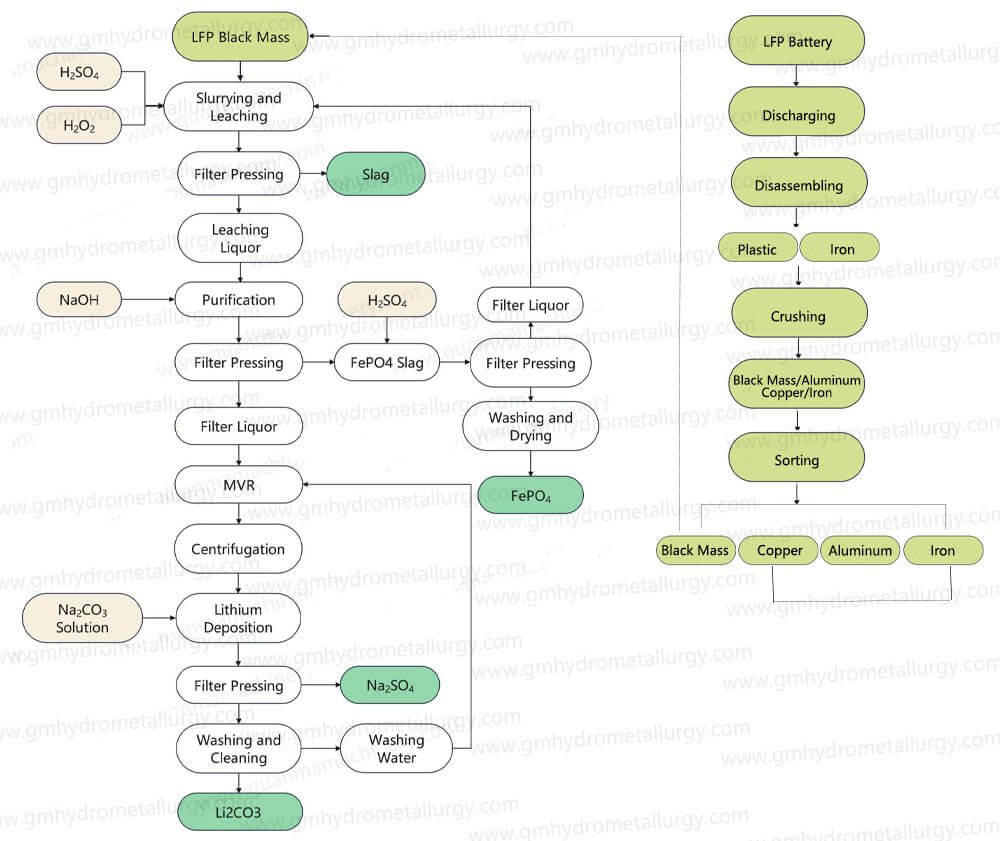

Hydrometallurgy Recycling Process

1. Pretreatment

Discharge, dismantle, crush, and sort spent LFP batteries. Recycle plastics and iron casings from dismantled components. Separate cathode materials (e.g., aluminum foil, binders, separators) via magnetic sorting to obtain phosphate iron lithium (LFP) cathode powder.

2. Leaching

Dissolve valuable metals (Li, Fe, P, etc.) from the black powder into a liquid phase using acidic/alkaline solutions.

3. Purification & Impurity Removal

Remove impurities (Fe, Al, Ca, Mg, etc.) from the leachate to ensure lithium purity.

4. Lithium Precipitation

Precipitate lithium salts (e.g., lithium carbonate) from the purified solution.

5. Concentration & Crystallization

Concentrate and crystallize the solution to recover cobalt/nickel salts (if present) and further refine lithium salts or byproducts.

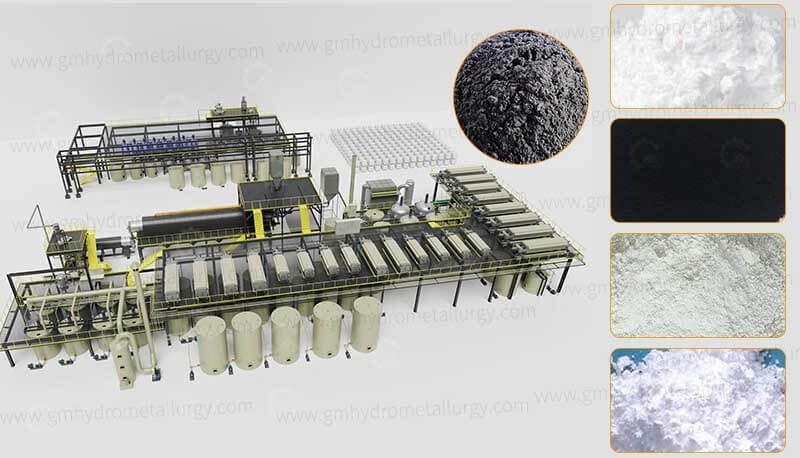

Raw Material&Final Product

Chemical Composition of LFP Battery Black Mass

| Battery Source | Black Mass | Li | Fe | P | Cu | Al | C |

| LiFe Battery BM | 100% | 2.74% | 21.3% | 13.4% | 2.8% | 1.04% | 32.06% |

| Not: This testing report is for Reference, if you have any testing report of the black mass, please share us. | |||||||

Input: LFP battery black mass, spent LFP batteries, LFP black slurry, LFP electrode cathode/anode slurry.

Key components: Phosphorus (P), lithium (Li), copper (Cu), iron (Fe), carbon (C), aluminum (Al).

Output: High-purity lithium carbonate, iron phosphate, carbon black amd aluminum hydroxide.

Finished Product Quality

| Name | Code | Outputs Name | Recovery Rate | Remark |

| Main Outputs | 1 | Coso | 95-98% | Battery Grade |

| 2 | NiSO | 95-98% | Battery Grade | |

| 3 | Mnso | 95-98% | Battery Grade | |

| 4 | LicO3 | 90-95% | Battery Grade | |

| Side Products | 5 | Cu | 95-98% | - |

| 6 | Fe | 95-98% | - | |

| 7 | AI | 95-98% | - |

Equipment Advantages

Advantages of lfp battery black mass hydrometallurgical recycling plant:

1. Simplified hydrometallurgical process suitable for industrial-scale production.

2. Proven technology with high metal recovery rates and product purity.

3. Flexible and easily controllable process parameters.

4. Low energy consumption and minimal environmental pollution.

5. Cost-effective, high-profit solution with efficient eco-friendly performance.

6. Enables targeted recovery of specific metals from battery waste.

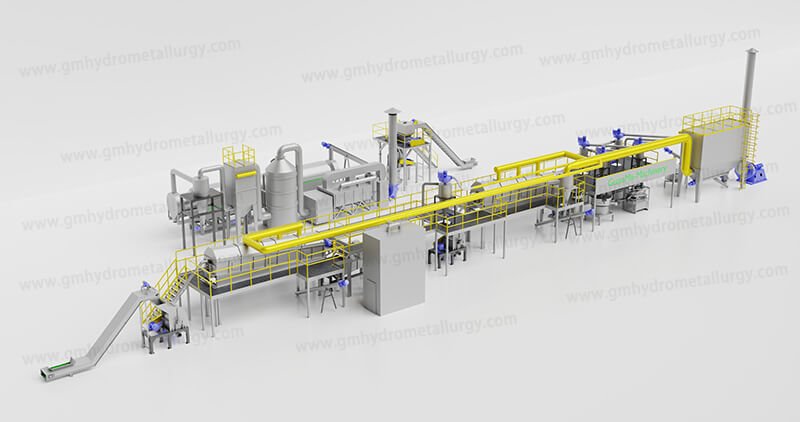

Supporting Equipment

Lithium Battery Crushing and Sorting Recycling Production Line

Scrap lithium battery recycling machine mainly use physical way to crushing and separation scrap lithium battery to get black mass, copper, aluminum, iron and separator.

If you want to start LFP battery black mass hydrometallurgical recycling machine business, please contact Guanma Machinery to get solutions and quotations!

Technical Parameter

LFP Battery Black Mass Hydrometallurgy Recycling Machine Technical Parameters

If you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Lithium Iron Phosphate (LFP) Black Mass | |||

| Model | Annual Capacity | Power/kw | Size |

| LBE-1000 | 1000tons | 340kw | About2350㎡ |

| LBE-2000 | 2000tons | 429kw | About3200㎡ |

| LBE-5000 | 5000tons | 580kw | About4352㎡ |

| LBE-10000 | 10000tons | 820kw | About5918㎡ |

| LBE-20000 | 20000tons | 1123kw | About8200㎡ |

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)