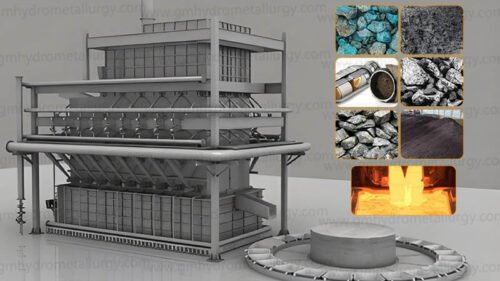

The Lead Smelting Rotary Furnace is mainly composed of the rotary furnace body,hydraulic transmission system, post-combustion device,sealing cover,ead discharge system,operating platform and control system.

Process description: lt effectively combines traditional precipitation smelting and reaction smelting, mainly smelting undesulfurized lead paste or desulfurized lead paste and lead grid, it designs with comprehensive position dust collection pipelines, adopts post-combustion mode and beam jet technology, which can increases the utilization rate of gas thermal energy by 20%, and effectively reducing the emission of exhaust gas and SO2.

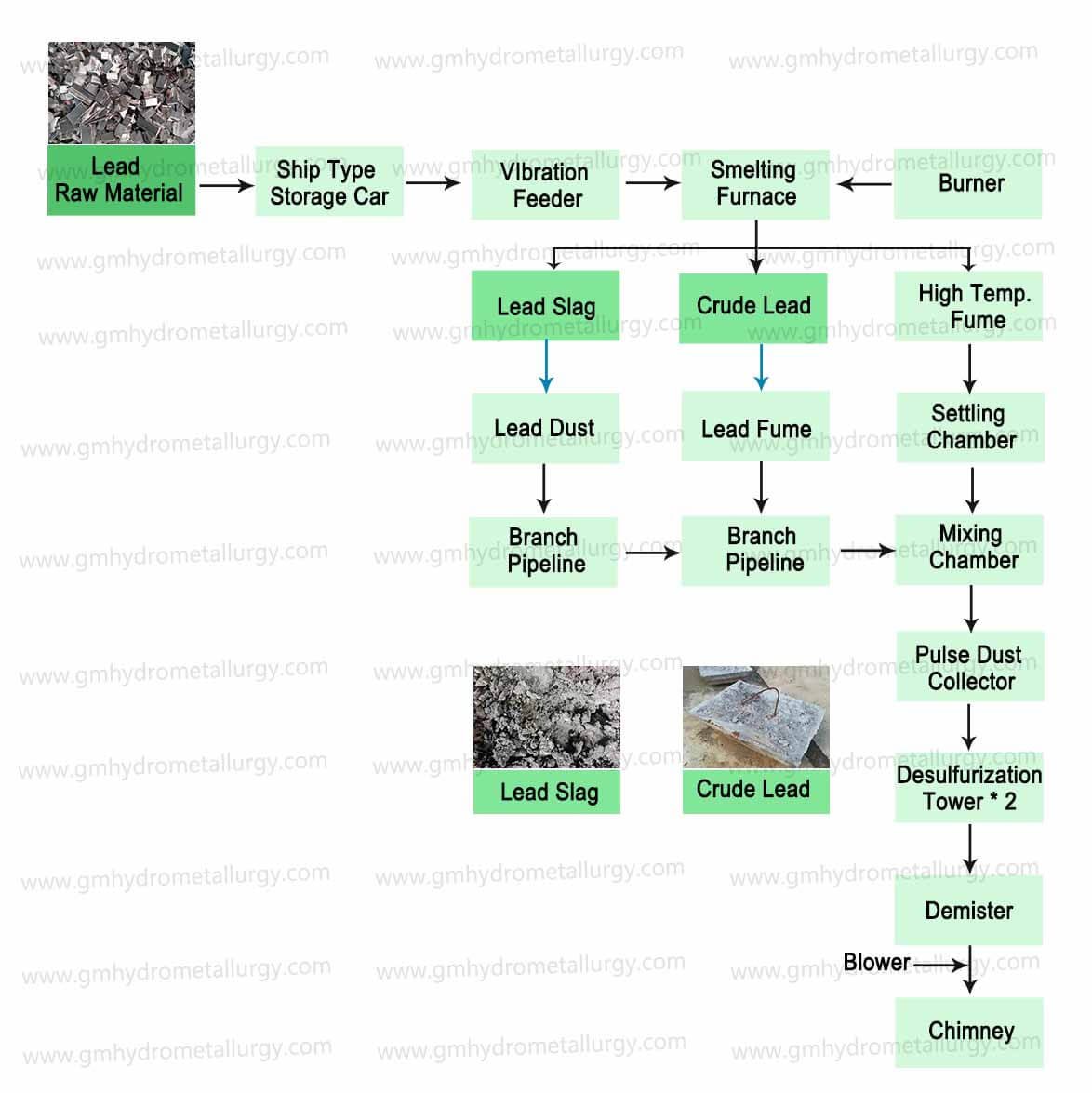

Crude Lead Rotary Furnace Process Flow

The smelting process in a crude lead rotary furnace can be divided into six steps:

1. Pre-heating

First, the temperature of the rotary furnace is raised to above 1000°C to bring it to operating condition.

2. Charging Stage

Lead ore is charged into the rotary furnace together with coal and limestone. The coal acts as a reducing agent, and the limestone serves as a flux/neutralizing agent.

3. Slag Formation (Slagging-off)

High-temperature air supplied from a hot blast stove causes the oxygen in the gases generated by the reaction between the reducing agent and the lead ore to be reduced by elements like iron and silicon present in the gas phase. This produces a solid residue known as slag (or specifically, slag formed by air injection).

4. Formation of Sponge Lead (“Lead Wool”)

After a period of reaction, a portion of crude lead, known as sponge lead (often colloquially called “lead wool”), is generated within the rotary furnace.

5. Determining Optimal Smelting Duration

Based on the quality, temperature, and impurity content of the sponge lead, the appropriate smelting duration is determined.

6. Lead Tapping

After the optimal smelting time has elapsed, the molten sponge lead flows out from the furnace’s taphole (or via tilting the furnace), forming crude lead.

Raw Material & Output

Equipment Advantages

PLC Control

The control system adopts PLC control, which can realize continuous feeding, automatic smelting and lead discharge.

High Purity Lead

The purity of crude lead can reach 95-98%, lead direct recovery rate can reach 99%, the lead content in slag is less than 2%.

Heat Energy Utilization Rate Increased By 20%

Which can increases the utilization rate of gas thermal energy by 20%, and effectively reducing the emission of exhaust gas and SO2.

Safety and Environmental Protection

Safety and environmental protection meet environmental protection requirements.

Technical Parameter

Lead Smelting Rotary Furnace Technical Parameters

If you have other requrement and want to know more details, please contact us +86 17838366846.(The data in this table are for reference only)

| ltems | Technical Data | ||

| Raw Materials Feeding Capacity | 5t/Furnace,10t/Furnace,20t/Furnace,40t/Furnace,60t/Furnace | ||

| Processing Capacity | 2t,3t,5t,10t,15t,20,25t,30t,40t,50t...Lead Contained Materials/Furnace | ||

| Rated Power | Based on Furnace Capacity | ||

| Furnace Size | Based on Furnace Capacity | ||

| Furnace Material | Boiler SteelQ345,Thickness: 20mm | ||

| Refractory Material | 18 Magnesia-Chrome Brick, Quantity: Based on Furnace Capacity | ||

| Rotation Angle | 360° | ||

| Rotation Speed | 0-1rpm | ||

| Smelting Time | 6~8h(Dependson Materials Condition) | ||

| Nature Gas Consumption | ≤300m3/h(Diesel Separately Calculated) | ||

| Discharged Crude Lead Purity | 95%-98% | ||

| Land Space Furnace | Based on Furnace Capacity | ||

| Environmental Protection Equipment | Based on Furnace Capacity | ||

High-capacity smelting solutions maximizing metal recovery rates.

Robust industrial smelting equipment ensuring process reliability.

Environmentally optimized designs for sustainable lead recycling.

Custom smelting solutions tailored to your specific slag handling and lead refining needs.

Equipped with crude lead refining furnace, after refining system, the purity of refined lead alloy ingots can reach 99.985%.

Experience the Guanma difference in lead recycling furnace technology. Contact us today for a custom quote and elevate your smelting operation with a furnace engineered for performance and durability.

Ready to optimize your lead processing? Guanma Machinery lead smelting rotary furnace manufacturer, delivers engineered excellence. Our lead smelting furnaces are built for peak thermal efficiency and heavy-duty construction, featuring superior refractory lining for extended furnace lifespan and reduced downtime.

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)