The lead refining machine produces high-purity cathode lead and residual anodes coated with anode slime. The cathode lead is washed, melted, refined, and cast into lead ingots. A portion of the cathode lead is used to create starter sheets. Residual anodes are stripped of anode slime, remelted, and recast into new anodes. The anode slime is filtered and further processed to recover valuable metals (e.g., Bi, Au, Ag).

Lead refining can be performed via pyrometallurgical or electrolytic methods. Electrolytic refining is generally preferred due to its higher productivity, ease of mechanization/automation, and ability to produce high-purity lead in a single step.

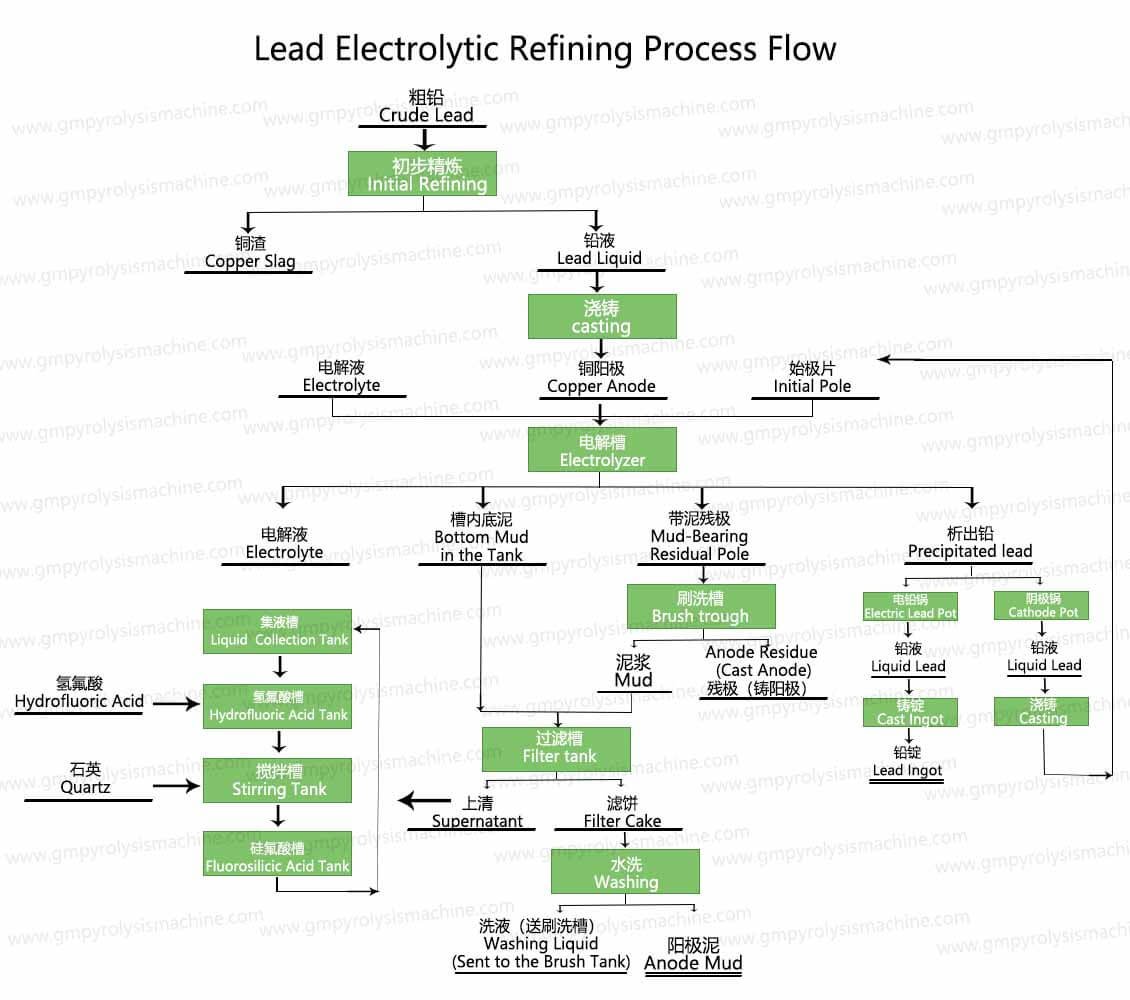

Lead Electrolytic Refining Process Flow

The process typically includes anode preparation, cathode preparation, electrolysis, electrolyte preparation, electrolyte purification, and anode slime treatment.

1. Raw Material Preparation

Lead-containing materials (e.g., lead sludge, lead-laden wastewater, lead ore, recycled lead products, lead-containing slag) are pretreated (filtered, dried, etc.) to remove impurities and ensure product purity.

2. Electrolytic Cell Design

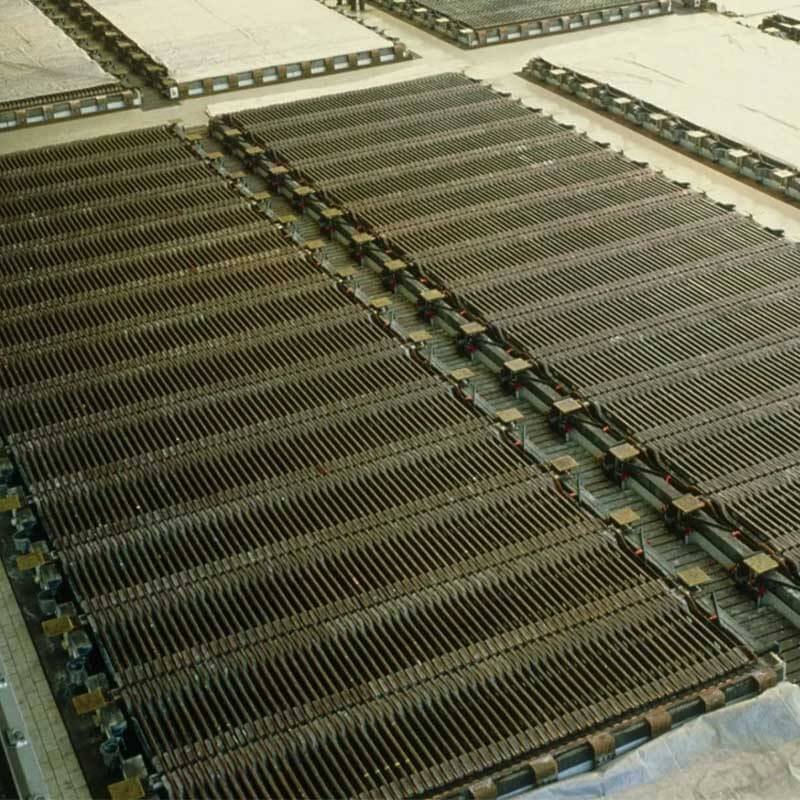

The electrolytic cell, a critical component, consists of cathodes, anodes, electrolyte, and cell walls.

3. Electrolysis Process

Pretreated lead-containing materials are loaded into the cell. Under an applied current, lead from the anode dissolves into the electrolyte and deposits onto the cathode as pure lead.

4. Product Separation

Post-electrolysis, the products (cathode lead and anode slime) are separated via filtration and drying.

5. Wastewater Treatment

Lead-contaminated wastewater generated during refining undergoes treatment to remove harmful substances, ensuring compliance with environmental standards.

6. Slag Treatment

Lead-containing slag is processed to extract residual valuable metals (e.g., Cu, Sn), minimizing resource waste.

Raw Material&Final Product

Raw Materials: Lead sludge, lead-laden wastewater, lead ore, recycled lead products, lead-containing slag.

Final Product: Refined lead (lead ingots).

Equipment Advantages

1. High Efficiency

Short processing cycles and rapid production.

2. Simplicity

Streamlined process, ideal for bismuth-rich crude lead, yielding high-purity lead in one step.

3. High Metal Recovery

Excellent direct recovery of lead and efficient recovery of Au, Ag, Bi, and other valuable metals.

4. Eco-Friendly

Integrated wastewater treatment ensures compliance with environmental regulations.

5. Low Cost

Minimal energy consumption and operational expenses.

Supporting Equipment

Electrolytic Cell

The lead electrolytic cell is a core component of lead production. It enables the electrolytic separation of lead by dissolving the lead anode into ions, which migrate through the electrolyte to the cathode and are reduced to metallic lead, facilitating lead production and recycling.

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)