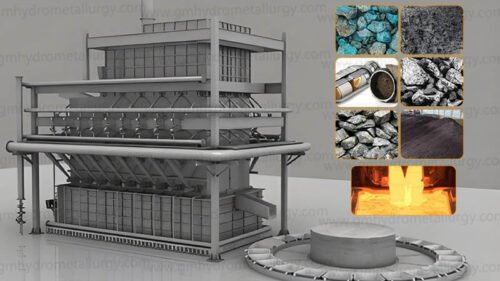

Professional Gold Electrolysis Plant for Gold-Loaded Carbon. Complete front-end adsorption & refining solution for high-purity gold recovery from loaded carbon.

What is Gold-Loaded Carbon?

Gold-loaded carbon is an intermediate product generated in the final stage of the gold smelting process, primarily composed of activated carbon material that has adsorbed gold elements. Through high-temperature incineration or chemical desorption processes, gold can be extracted with a recovery rate reaching over 90%.

Raw Material & Output

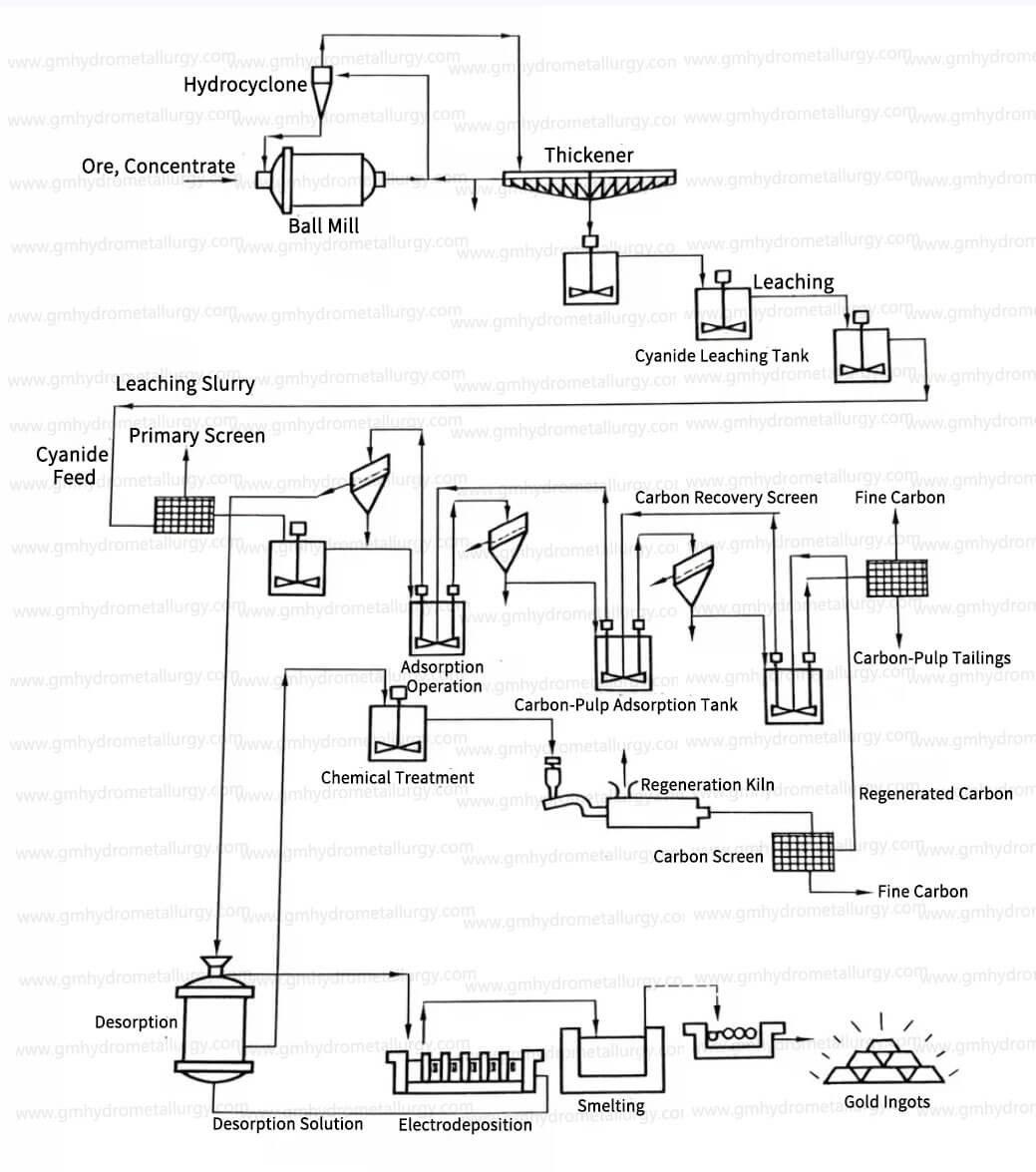

Core Process Workflow of Gold Electrolysis Plant for Gold-Loaded Carbon

Our plant combines multiple core operations including pre-screening, cyanide leaching, adsorption, desorption, electrolysis (or electrowinning), and carbon regeneration, forming a closed-loop and efficient production system.

1. Pre-Screening

Purpose: Remove wood chips and debris from the pulp to prevent clogging and interference in subsequent stages. Typically uses a 28-mesh (0.6mm) screen.

2. Cyanide Leaching & Desliming

Pulp from the leaching circuit is fed into the adsorption section. Prior to adsorption, 1-2 stages of desliming remove fine wood chips which can adsorb gold-cyanide complexes and reduce carbon adsorption efficiency.

3. Adsorption (CIP/CIL)

Pulp flows continuously through a series of adsorption tanks. Fresh activated carbon is added to the last tank and moved counter-currently to the pulp flow via airlift or pump. Loaded carbon from the first tank is screened, washed, and prepared for desorption.

4. Desorption

Gold is stripped from the loaded carbon. We offer multiple robust methods:

Atmospheric Desorption Method

Gold is desorbed from gold-loaded carbon using a solution containing 1% sodium cyanide and 1% sodium hydroxide at 85℃ under normal pressure. This method is cost-effective and easy to operate.

Alcohol Desorption Method

Under normal pressure and 80℃, the desorption solution is composed of 0.1% sodium cyanide, 1% sodium hydroxide, and 20% alcohol (by volume), which can accelerate the desorption rate.

High-Pressure Desorption Method

Gold-loaded carbon is desorbed with a solution of 0.1% sodium cyanide and 1% sodium hydroxide at 160℃ and 3.5×10⁵Pa for 2-9 hours, suitable for large-scale and high-efficiency production.

5. Electrolysis

The purified gold-cyanide solution (eluent) is passed through electrolytic cells equipped with multiple cathode and anode pairs.

This results in a gold deposition rate exceeding 99%. The spent electrolyte can be replenished with NaCN and NaOH for reuse in desorption or returned to leaching.

6. Carbon Regeneration

To restore adsorption activity, carbon undergoes a two-stage regeneration:

Acid Wash: Removes calcium carbonate and most base metal complexes.

Thermal Activation: Heats in a kiln to volatilize and remove organic and other inorganic contaminants, readying the carbon for re-use in adsorption.

Whether you’d like to learn about gold refining machine or precious metal electrolysis recovery equipment, feel free to contact us!

Key Advantages

Compared to traditional cyanidation-zinc precipitation circuits, our plant offers significant benefits:

Reduced Capital & Operational Cost

Maximized Profitability: Eliminates solid-liquid separation and large filtration/decanter equipment. Saves up to 10% in capital investment and lowers operating expenses.

Superior Recovery for Complex Ores

It can achieve higher gold recovery rates when processing low-grade and refractory raw ores, especially suitable for ores with high mud content that are difficult to settle and filter, and ores where fine mud adsorbs dissolved gold.

Higher Gold Purity & Smelting Efficiency

Produces high-purity gold cathode sludge. This leads to reduced flux consumption during smelting and minimizes gold losses in slag and fumes.

Compact Footprint & Simplified Process Flow

Integrated design requires less space and offers easier operation and maintenance.

Choose Our Gold Electrolysis Plant for Gold-Loaded Carbon

Whether you are engaged in large-scale gold smelting or processing of low-grade gold ores, our Gold Electrolysis Plant for Gold-Loaded Carbon can provide you with customized, efficient, and cost-effective gold extraction solutions. Contact us today to learn more about the equipment details and quotation!

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)