The Crude lead refining furnace is mainly composed of refining furnace, refining pot, dust collecting hood, operating platform, linear casting machine, lead fume purifier and control system(Final configuration may vary based on client requirements and the desired end product).

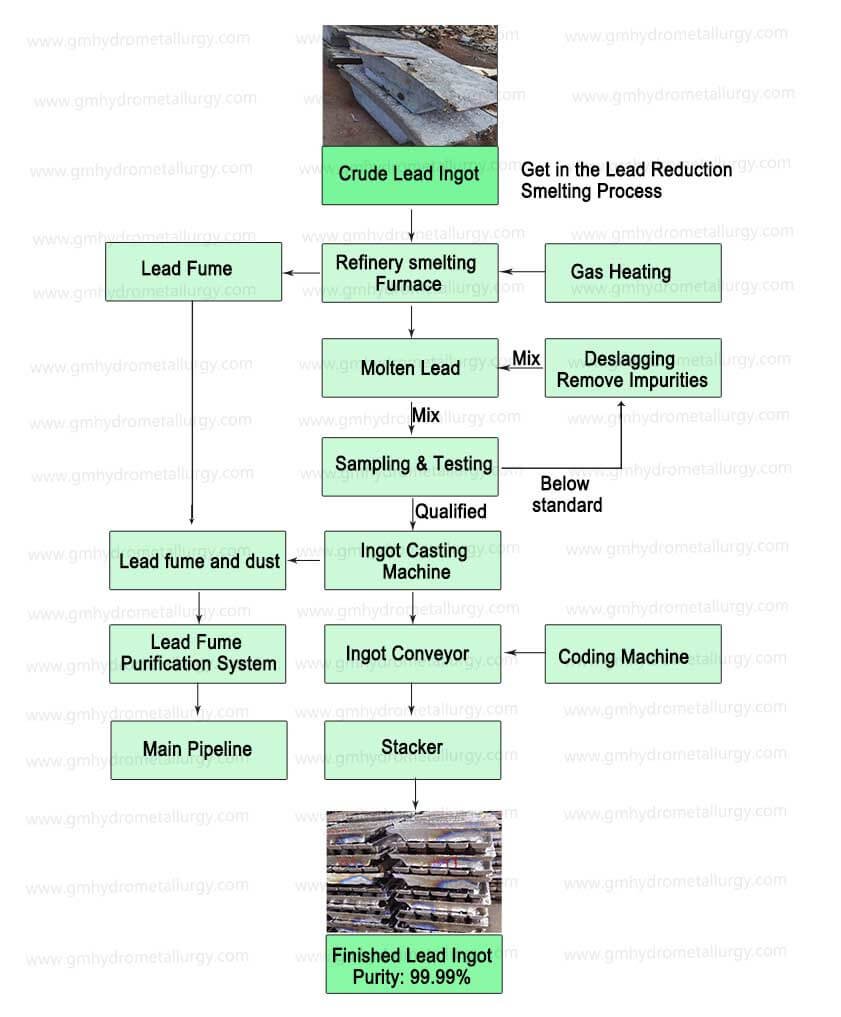

Crude Lead Refining Plant Process Flow

Lead Refining Process Description:

1. Charging

Charge the refining furnace or kettle to ~80% capacity with recycled crude lead (e.g., from smelting) or lead battery grids.

2. Heating & Melting

Heat and stir the lead charge until fully molten.

3. Impurity Removal

Add various refining agents and stir. Skim off dross (impurities) after reactions complete.

4. Quality Control

Test the molten refined lead to determine its elemental composition.

5. Alloying

Sequentially add precise amounts of alloying elements (e.g., Calcium, Tin) to produce lead alloys as required.

6. Casting Preparation

Sequentially activate the Linear Casting Machine’s: Chain Conveyor, Circulating Cooling Water System, Ingot Marking/Stamping Machine, Lead Ingot Conveyor.

7. Casting

Tap the molten refined lead alloy into the casting machine to form ingots.

Following processing in the lead refining plant, the resulting refined lead alloy ingots achieve a purity level of 99% to 99.9999%.

Raw Material & Output

Crude Lead ingot purty: 95%-98%, Lead ingot purity : 99%-99.9999%.

Equipment Advantages

Maximize your lead refining productivity and output purity with Guanma Machinery Lead Refining Furnace Systems.

Ultra-High Purity Output (99% – 99.9999%)

Produce premium-grade refined lead ingots consistently meeting stringent purity standards for specialty alloys, batteries and high-value applications, Ultra-High Purity Output (99% – 99.9999%).

Resource Recovery

Maximize lead yield from scrap (battery grids, crude lead) and reclaim valuable metals from dross.

Environmental Compliance & Safety

Advanced Lead Fume Gas Purification System effectively captures and treats emissions (Pb dust, SO₂), ensuring strict adherence to environmental regulations.

Flexibility & Product Control

Modular design supports various feedstocks (crude lead, recycled scrap) and final product specifications (ingots, anode plates).

Automated Operation

Fully coordinated Linear Casting Machine ensures smooth, automated ingot production (uniform weight, cooling, stamping, stacking).

Reduced Footprint & Scalability

Compact Layout, Efficient integration of refining furnace, furnace, fume hood, and casting line optimizes floor space utilization. Systems available from pilot scale to high-capacity production lines, tailored to your throughput needs.

Request a detailed quote for our high-efficiency Lead Refining Equipment today!

Technical Parameter

Crude Lead Refining Furnace Technical Parameters

If you have other requrement and want to know more details, please contact us +86 17838366846.(The data in this table are for reference only)

| ltems | Technical Data | ||

| Capacity of the Lead Refinery Furnace | 30t,60t,100t,120t/Furnace | ||

| Quantity of the Lead Refinery Furnace | Based on Processing Capacity | ||

| Melting Temp | 400~650°C | ||

| Heating Type | NGP+Compressed Air | ||

| Power of Burner Blower | Based on Processing Capacity | ||

| NGP Consumption | 60-200m³/h,Two Burners/Furnace | ||

| Ingot Casting Capacity | 10-30 t/h | ||

| Consumption of Circulation Cooling Water | 5-20m³/h | ||

| Lead Ingot Weight | 25kg,45kg | ||

| Lead Ingot Purity | 99%~99.9999%(Provide solutions according to customer needs) | ||

| Total Power | Based on Processing Capacity | ||

| Customized solutions based on customer raw materials, capacity and final products | |||

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Sample Testing

According to the customer's raw materials, test and send the final sample product. come out testing report to help clients analyze the project.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Technical Upgrade Support

Technical updates for equipment are available throughout the production cycle. If clients request upgrades, only material costs will be charged.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)