Principle of Tin Electrolytic Refining

Tin electrolytic refining utilizes the property that tin dissolves in specific electrolytes. Under direct current, tin dissolves from the impure tin anode and deposits as high-purity metal tin on the cathode, while impurities remain in the anode slime or electrolyte.

Objective

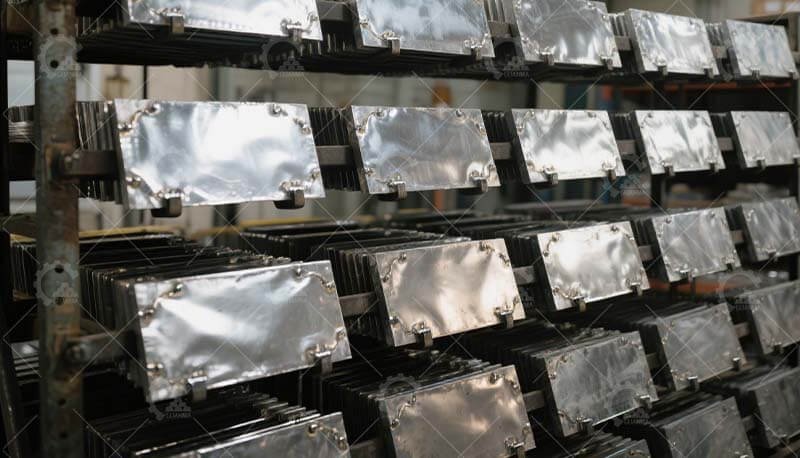

To produce qualified refined tin or refined solder tin (cathode). Crude solder electrolysis employs a tin-lead alloy anode and thin cathode sheets cast from electrolytic tin. Within a fluosilicate electrolyte solution and under direct current, the anode undergoes electrochemical dissolution. Tin and lead ions enter the electrolyte and deposit on the cathode, separating from other impurities to yield purified tin-lead alloy.

Key Reactions:

Anode: Sn-2e=Sn²⁺; Pb-2e=Pb²⁺

Cathode: Sn²⁺+2e=Sn;Pb²⁺+2e=Pb

Process Outcome:

The electrolytic refining of crude solder produces qualified solder tin (cathode) and residual anodes coated with anode slime. Part of the cathode material is further processed into commercial solder, while the remainder is used to fabricate new cathode (starter) sheets. Residual anodes are cleaned of slime, remelted, and recast for further electrolysis. Anode slime can be processed to recover valuable metals such as silver and bismuth.