Navigating the complex world of precious metal recovery requires understanding the core precious metal refining methods. Whether you’re a jeweler, electronics recycler, dental lab, or industrial supplier, choosing the optimal refining process directly impacts your profitability and environmental compliance.

1. Fire Assay: The Gold Standard for Accuracy

Process

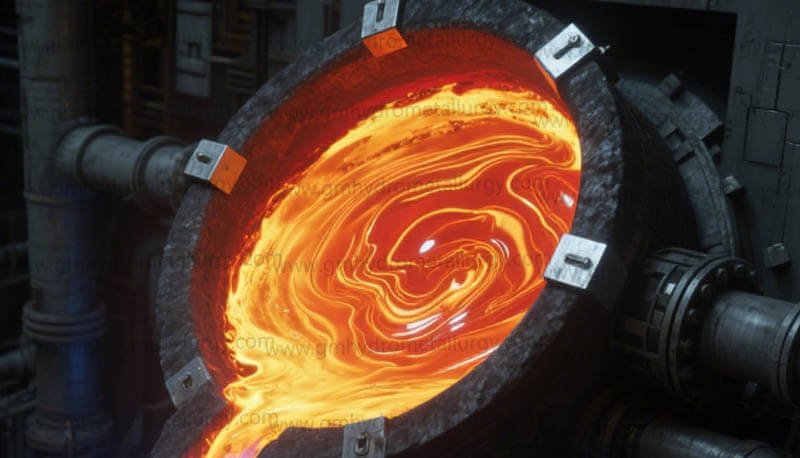

This ancient, highly trusted method involves melting the sample with a flux (like lead oxide and borax) in a crucible at high temperatures (over 1100°C). Precious metals dissolve into the molten lead button formed.

Best For

Highly accurate quantitative analysis and refining of gold and silver, especially from ores, concentrates, and high-value scrap. It’s the benchmark for gold purity assessment.

Key Advantages

Unmatched accuracy for Au/Ag, handles complex matrices.

Long-Tail Focus

high-purity gold fire assay, accurate precious metal content analysis, doré bead refining process.

2. Chemical Leaching & Precipitation: Selective Extraction Power

Process

This involves dissolving the target precious metals out of the scrap material using specific chemical solutions, while leaving impurities behind. Common lixiviants include:

Cyanidation (Au/Ag)

Dilute sodium cyanide solution dissolves gold and silver (requires strict environmental controls).

Aqua Regia (Au/Pt/Pd)

A potent mix of nitric and hydrochloric acid dissolves gold and platinum group metals (PGMs).

Acid Leaches (Ag)

Nitric acid is commonly used for silver dissolution (e.g., from photographic waste, silver contacts).

Once dissolved, the precious metals are recovered from the solution through precipitation or adsorption.

Best For

Extracting metals from lower-grade materials, electronic scrap (e-waste), catalysts, specific industrial residues. Highly versatile.

Key Advantages

Can handle complex and lower-grade materials, relatively scalable, selective.

3. Electrolysis: Achieving Ultra-High Purity

Process

An electrochemical technique.

Electrowinning

Used to recover dissolved metals (e.g., from a leaching solution) onto cathodes. Impure metal acts as the anode; pure metal deposits onto the cathode when an electric current is applied. Common for copper, also used for gold and silver.

Electrorefining

Takes a relatively pure anode (like a doré bar or impure cast metal) and dissolves it electrolytically. The target precious metal deposits in high purity (>99.99%) onto the cathode, while impurities either dissolve or fall as sludge.

Best For

Producing the highest purity gold and silver (often 999.9+ fineness) from relatively pure feed material (like doré bars or recovered anode slimes). Crucial for investment-grade bullion and high-tech applications.

Key Advantages

Delivers exceptional purity, well-established for Au/Ag.

4. Solvent Extraction (SX) & Ion Exchange (IX): Modern Separation Science

Process

These advanced techniques focus on separating individual precious metals from complex solutions (often leach solutions) with high selectivity.

Solvent Extraction

Uses organic solvents containing specific extractants that selectively bind to one metal ion over others. The metal is transferred (“extracted”) from the aqueous leach solution into the organic solvent. It’s then stripped back into a clean aqueous solution using a different chemical, resulting in highly purified metal concentrates.

Ion Exchange

Uses specialized resins packed in columns. As the solution passes through, metal ions selectively bind to sites on the resin beads based on their charge and chemistry. Different metals are eluted (washed off) separately using specific solutions.

Best For

Complex mixtures, especially critical for efficiently separating Platinum Group Metals (PGMs – Pt, Pd, Rh, Ir, Ru, Os) from each other and from base metals/gold. Also used in advanced gold refining.

Key Advantages

High selectivity for difficult separations (especially PGMs), efficient, produces very pure individual metal solutions, scalable.

Choosing the Right Precious Metal Refining Method Matters

The optimal path depends critically on your material type, volume, target metals, desired purity, environmental considerations, and budget. High-volume electronic scrap often starts with leaching, while doré bars head straight to electrolysis. Complex PGM-bearing catalysts demand sophisticated SX/IX.

Partner with Expertise for Maximum Recovery & Value

Don’t gamble with your valuable scrap. Partner with a reputable refiner like Guanma Machinery who masters the full spectrum of precious metal refining methods. We leverage our deep metallurgical expertise to analyze your material and recommend the most efficient, secure, and profitable refining solution – whether it’s high-yield chemical processing, ultra-pure electrolytic refining, or advanced PGM separation.

Get a Free Consultation & Quote Today!

Maximize your returns. Contact our refining specialists to discuss your specific material and discover how our tailored precious metal recovery processes unlock its true value.