Precious Metal Recovery from Electronic Waste Solutions

What is Electronic Waste?

Electronic waste (e-waste) includes discarded products, scraps, waste printed circuit boards, and obsolete electronics such as computers, appliances, and mobile phones generated during the manufacturing or end-of-life phases of electronic components and devices.

Why Recycle Electronic Waste?

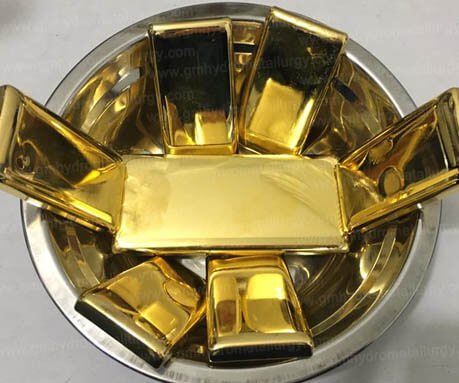

Rough estimates indicate that: 5 million computers contain approximately 4.2 tons of Au (gold), 30 tons of Ag (silver), and 1.5 tons of Pd (palladium). 50 million mobile phones contain approximately 140 kg of Au, 1 ton of Ag, and 50 kg of Pd. In total, this amounts to 4.34 tons of Au, 31 tons of Ag, 1.55 tons of Pd, and small quantities of Pt (platinum)—a significant wealth of resources.

Solutions

To efficiently recover these valuable resources, Guanma Machinery adheres to a green and environmentally friendly recycling philosophy, offering high-efficiency solutions for extracting precious metals from e-waste. Below are detailed introductions to several common solutions and their key equipment:

1. Pyrometallurgy

Principle

Separates precious metals from impurities through high-temperature smelting, leveraging differences in metal melting points for enrichment or extraction.

Process

Pretreatment: Crushing and sorting e-waste to remove non-metallic components.

Smelting: Melting metals into alloys using high-temperature furnaces (e.g., arc furnaces, induction furnaces) with flux agents (e.g., borax, sodium carbonate).

Refining: Isolating precious metals via electrolysis or chemical methods (e.g., electrolytic refining of gold and silver).

Key Equipment

Crusher: Mechanically breaks down e-waste (e.g., circuit boards).

Smelting Furnace: Induction furnace, arc furnace (temperatures exceed 1200°C).

Electrolytic Cell: Purifies precious metals through electrolysis.

2. Hydrometallurgy

Principle

Dissolves precious metals using chemical solvents, followed by separation via displacement, precipitation, or extraction.

Process

Pretreatment: Mechanical shredding and magnetic separation of metals from non-metals.

Leaching: Dissolving precious metals with solvents (e.g., nitric acid for silver).

Separation and Purification:

Chemical Precipitation: Adding reducing agents (e.g., sodium sulfite) to precipitate metals.

Solvent Extraction: Selectively isolating metal ions with extractants.

Key Equipment

Reactor: Acid/alkali-resistant containers (e.g., FRP reaction tanks).

Filtration Equipment: Filter press, centrifuge.

Extraction Equipment: Centrifugal extractors, mixer-settlers.

3. Mechanical-Physical Separation

Principle

Separates precious metal particles based on physical properties (density, magnetism, conductivity).

Process

Crushing: Shredding e-waste into fine particles.

Sorting:

Eddy Current Separation: Isolates non-ferrous metals (e.g., copper, aluminum).

Electrostatic Separation: Leverages conductivity differences to sort precious metals.

Gravity Separation: Uses density differences (e.g., shaking tables, centrifuges).

Key Equipment

Eddy Current Separator: Separates non-ferrous metals.

High-Voltage Electrostatic Separator: Sorts micron-level metal particles.

Centrifugal Shaking Table: Density-based sorting.

4. Electrolysis

Principle

Electrochemically deposits precious metals from ionic solutions (commonly used in refining).

Process

Pretreatment: Dissolving precious metals into ionic solutions (e.g., cyanide gold solution).

Electrolysis: Applying electric current in an electrolytic cell to deposit metals onto the cathode.

Key Equipment

Electrolytic Cell: Corrosion-resistant materials (e.g., titanium or graphite electrodes).

DC Power Supply: Provides stable current.

If you are planning to start a business in recovering precious metals from electronic waste, Guanma Machinery, a professional supplier of precious metal recycling equipment, offers tailored solutions. Get a tailored solution and quote now!

Technical Parameter

Solution Selection Recommendations

If you have other requrement and want to know more details, please contact us.

| Solution Selection Recommendations | |

| Capacity | Recommended Solution |

| 0.05-100ton/day | Pyrometallurgy |

| 0.1-1000ton/day | Hydrometallurgy |

| 0.1-1000ton/day | Electrolysis |

| 0.1-5ton/day | Mechanical-Physical Separation |

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)