Solution for Platinum-Rhodium Recovery from Waste Refractory Bricks and Glass Cullet in Fiberglass Industry

Origin of Platinum-Rhodium

Platinum-rhodium alloy crucibles, bushings, and spinnerets used for melting glass and producing fiberglass operate long-term at high temperatures of 1200–1300°C. During this process, portions of platinum (Pt) and rhodium (Rh) oxidize into volatile PtO₂ and Rh₂O₃. These oxides diffuse into the furnace’s refractory bricks or become entrapped within glass cullet. This waste material typically contains (%) SiO₂ 46–54, Al₂O₃ 39–50, CaO+MgO ~2, with approximately 2000 g/t Pt and 200 g/t Rh.

Methods for Platinum-Rhodium Recovery

Direct oxidative acid leaching of platinum and rhodium from this waste is challenging. The conventional approach involves separating silicon and aluminum oxides to concentrate the platinum and rhodium.

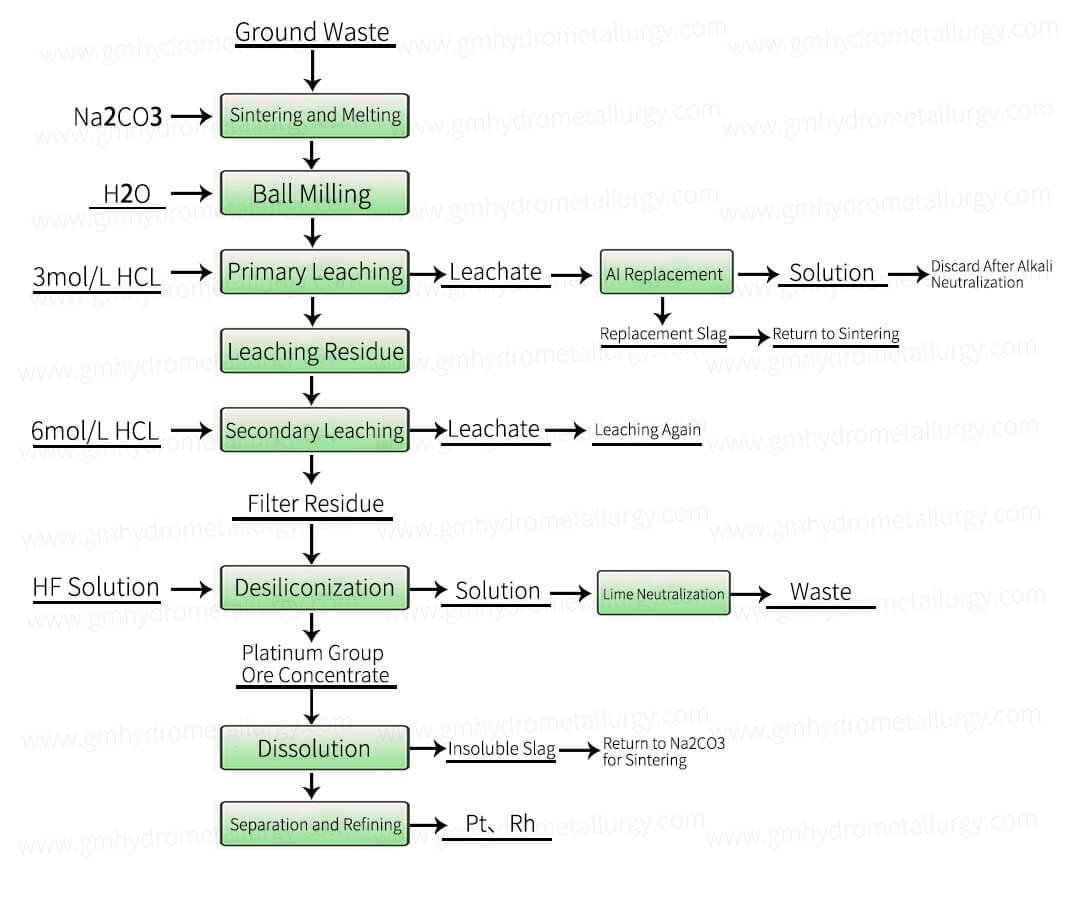

Process Flow for Platinum-Rhodium Recovery from Waste Refractory Bricks and Glass Cullet in Fiberglass Industry

1. Sintering/Melting

The waste material is blended with sodium carbonate (Na₂CO₃) and sintered/melted at approximately 1000°C. This converts the silicon and aluminum oxides into soluble sodium silicate and sodium aluminate:

Na₂CO₃ + 2SiO₂ → Na₂O·2SiO₂ + CO₂↑

Na₂CO₃ + Al₂O₃ → Na₂O·Al₂O₃ + CO₂↑

Na₂CO₃ + 6SiO₂ + Al₂O₃ → Na₂O·Al₂O₃·6SiO₂ + CO₂↑

2. Grinding & Leaching

The molten product is cooled, crushed, and ground finely in a ball mill with water to form a slurry. Hydrochloric acid (HCl) is added to dissolve the sodium silicate and sodium aluminate:

Na₂O·2SiO₂ + 2HCl + H₂O → 2NaCl + 2H₂SiO₃

Na₂O·Al₂O₃ + 8HCl → 2AlCl₃ + 2NaCl + 4H₂O

Na₂O·Al₂O₃·6SiO₂ + 8HCl + 2H₂O → 2AlCl₃ + 2NaCl + 6H₂SiO₃

3. Solid-Liquid Separation

A flocculant is added to promote the settling of fine solid particles. The slurry is then filtered.

4. Displacement & Filtration

Aluminum (Al) powder is added to the filtrate to displace any remaining dissolved platinum group metals (PGMs). The final filtrate, containing Pt < 0.004 g/L, is discarded.

5. Silica Removal & Concentration

The acid-insoluble residue, now enriched in PGMs, is treated with hydrofluoric acid (HF) to dissolve residual silica (SiO₂). This yields a concentrate containing approximately 50% platinum and rhodium.

The platinum-rhodium concentrate is dissolved using aqua regia or HCl + NaClO₃. The resulting solution is then processed using selective precipitation or solvent extraction methods to separate and refine the platinum and rhodium into pure metal products.

Alternative Method

Lime (CaCO₃) powder can be used instead of sodium carbonate. The lime is mixed with the refractory brick powder and sintered at 1300°C. This converts the silicon and aluminum oxides into acid-soluble calcium silicate and calcium aluminate. Subsequent HCl dissolution is followed by alkaline leaching to dissolve silicic acid colloids. The final insoluble residue constitutes the platinum-rhodium concentrate.

For more solutions on platinum-rhodium recovery from waste refractory bricks and glass cullet in the fiberglass industry, contact Guanma Machinery — PGM recovery equipment manufacturer!

Our Services

Production Flow Diagram

Complimentary provision of production flow diagrams and installation foundation drawings for buyer-required equipment.

Site Layout

Free adjustment services for layout plans during the entire operational process, provided upon buyer request.

Installation Training

During installation and trial operation, our engineers will be dispatched on-site for equipment installation, commissioning, and necessary operational training.

Accessories Supply

A list of wear-prone and consumable parts is provided. Spare parts are sold at factory prices when purchased directly from Guanma Machinery.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What type of precious metal do you want to extract?

2-How many tons raw material do you want to process per kg?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)