As India accelerates its transition to electric vehicles (EVs) and renewable energy storage, the demand for efficient lithium ion battery recycling black mass solutions has skyrocketed. However, outdated infrastructure and fragmented supply chains often hinder progress. This case study explores how a pioneering Indian recycler partnered with us to overcome these barriers using cutting-edge Lithium Ion Battery Recycling Black Mass Equipment—and transformed their operations.

The Challenge: Outdated Technology, Rising Costs

A Mumbai-based recycling company faced mounting obstacles:

Inefficient Black Mass Recycling Process: Their manual sorting and outdated machinery recovered only 65% of valuable metals (lithium, cobalt, nickel), leaving revenue on the table.

Unpredictable Lithium Ion Battery Black Mass Price: Market volatility made budgeting difficult, eroding profit margins.

Regulatory Pressure: New Indian e-waste mandates required higher recovery rates and stricter environmental compliance.

The client needed advanced black mass recycling plant equipment to modernize operations, stabilize costs, and meet regulatory demands—fast.

Our Solution: Tailored Lithium Ion Battery Recycling Black Mass Equipment

We delivered a turnkey solution, including:

1. Automated Black Mass Processing Systems

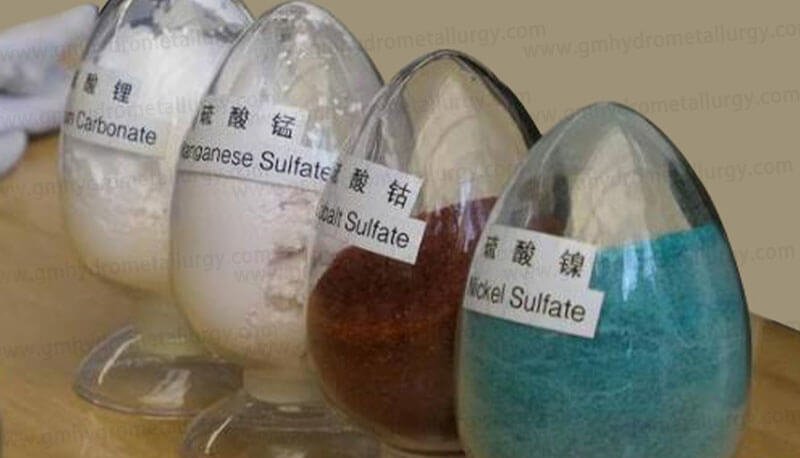

Our modular Lithium Ion Battery Black Mass Recycling Machine integrated shredding, sorting, and hydrometallurgical extraction technologies. This streamlined the black mass recycling process, achieving 92% metal recovery rates—up from 65%.

2. Localized Technical Support

On-site engineers trained the team to operate the equipment, while remote monitoring ensured minimal downtime.

3. Sustainability Compliance Packages

Emission control systems and waste reduction protocols aligned the facility with India’s Extended Producer Responsibility (EPR) regulations.

Results: Efficiency, Profitability, and Growth

Within 4 months of installing the Lithium Ion Battery Recycling Black Mass Equipment, the client reported:

40% Increase in Processing Capacity: From 500 to 700 tons of black mass lithium ion battery material monthly.

28% Higher Profit Margins: Stabilized lithium ion battery black mass price strategies and reduced material loss.

Zero Regulatory Penalties: Full compliance with India’s e-waste management rules.

15% Energy Savings: Energy-efficient equipment cut operational costs.

“This partnership was a game-changer,” said the client’s CEO. “The advanced black mass recycling plant equipment not only future-proofed our operations but positioned us as a leader in India’s circular economy.”

Why Global Recyclers Trust Our Lithium Ion Battery Recycling Solutions

End-to-End Expertise: From Lithium Ion Battery Recycling Black Mass Equipment sourcing to installation, we handle every detail.

Cost Transparency: Dynamic pricing models mitigate risks linked to lithium ion battery black mass price fluctuations.

Scalable Technology: Modular systems grow with your business, whether processing 100 or 10,000 tons annually.

Sustainable Outcomes: Our closed-loop black mass recycling process recovers >90% of critical minerals, reducing reliance on mining.

Powering India’s Green Energy Revolution

India’s EV and energy storage sectors are projected to generate 250,000 tons of spent lithium-ion batteries annually by 2030. By investing in robust Lithium Ion Battery Recycling Black Mass Equipment, recyclers can tap into this $3.2 billion opportunity while advancing sustainability goals.

Our client’s success underscores how the right technology partner can turn regulatory challenges into competitive advantages—and outdated processes into profitable, eco-friendly operations.

Ready to upgrade your black mass recycling plant?

Guanma Machinery delivers cutting-edge Lithium Ion Battery Recycling Black Mass Line tailored to India’s unique market needs. Contact us today to schedule a free consultation.