The lithium-ion battery pyrometallurgical recycling process, also known as high-temperature metallurgy, is a technique that recovers valuable metals from batteries through high-temperature thermal treatment. Its core principle involves roasting the electrode active materials at high temperatures, enabling the recovery of metal elements in the form of metallic simples or alloys.

Specific Steps of the Pyrometallurgical Recycling Process

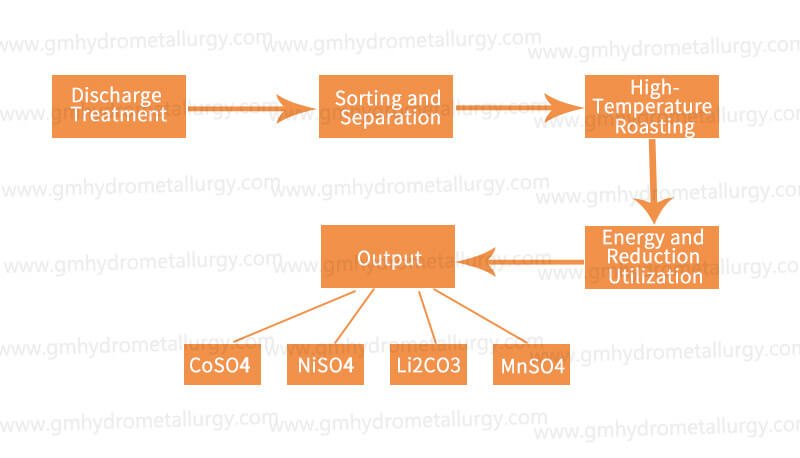

This process primarily includes the following steps:

1. Automatic Discharge Treatment

Firstly, spent batteries undergo a thorough automatic discharge to ensure the safety of subsequent operations.

2. Sorting and Separation

Batteries are sorted by type, and metal casings are separated from electrode materials using physical methods like vibratory screening and magnetic separation.

3. High-Temperature Roasting Treatment

The electrode materials are placed into a submerged arc furnace for processing at extreme temperatures exceeding 1000°C.

4. Energy and Reduction Utilization

During this stage, combustibles such as plastics, separators, and organic solvents are burned, providing energy for the reaction. Simultaneously, the reducing gases (e.g., carbon monoxide) produced by their combustion effectively protect the metal elements from excessive oxidation.

5. Output Processing

Finally, a fine powdered material containing metals and metal oxides is obtained through screening. The newly formed alloy (typically cobalt, nickel, copper alloy) can be further separated and purified through hydrometallurgical processes.

Main Advantages of Pyrometallurgical Recycling

The advantages of pyrometallurgy lie in its simple operation, high process maturity, and low requirements for feedstock composition. It can handle different types and models of lithium-ion batteries, making it suitable as a preliminary treatment method.

Disadvantages and Challenges of Pyrometallurgy

Despite its maturity, the process has significant drawbacks:

Low Lithium Recovery Rate

High temperatures cause lithium to enter the slag as oxide, making it difficult to recover effectively and leading to resource waste.

Inability to Recover All Materials

Electrolytes, separators, and anode graphite are burned during this process and cannot be recovered.

High Energy Consumption and Potential Pollution: Maintaining high temperatures requires substantial energy, and incomplete combustion of organics can produce harmful gases like dioxins, creating environmental pressure.

Poor Economic Feasibility

Due to the above disadvantages, its overall economic and environmental friendliness are relatively poor, hindering large-scale industrial production.

Technical Challenges in Pyrometallurgical Recycling

The core challenge of this process lies in how to efficiently and thoroughly separate organic impurities (like films and plastics) from the electrode metal materials in the pre-treatment stage. This is crucial to reducing polluting gases generated during subsequent combustion and improving the purity of the recovered metal products.

Guanma Machinery’s Combined Recycling Process (Pyrometallurgy & Hydrometallurgy)

To address the limitations of standalone pyrometallurgy, Guanma Machinery employs a combined pyro-hydrometallurgical process. The electrode materials are first treated via pyrometallurgy to generate a metal alloy. This alloy then serves as feedstock for subsequent hydrometallurgical recovery processes (such as acid leaching and solvent extraction). This approach enables the efficient, high-purity separation and extraction of various metal elements, enhancing overall recovery rates and economic value.