Hydrometallurgy vs Pyrometallurgy Battery Recycling

The exponential growth in electric vehicles and portable electronics has created an urgent need for efficient, sustainable battery recycling. At the heart of this challenge lies a critical technological choice: hydrometallurgy vs pyrometallurgy battery recycling.

Pyrometallurgy: Harnessing High Temperatures

Pyrometallurgical recycling employs intense heat, typically in furnaces exceeding 1400°C. Whole or shredded batteries are smelted.

How it Works: Organic components (electrolytes, separators, plastics) burn off, providing some energy. Metals are reduced, forming a molten alloy (typically cobalt, nickel, copper). Lithium, aluminum, and manganese report primarily to the slag phase, requiring further complex processing for recovery.

Key Advantages:

Robustness: Tolerates mixed or unknown battery chemistries well.

Established Scale: Proven in large-scale operations for other metals.

Simplicity (Initial): Fewer process steps initially compared to complex hydrometallurgical flowsheets.

Key Limitations & Challenges:

Lower Metal Recovery Rates: Significant losses of lithium (>70% often unrecovered), manganese, and aluminum to slag. Limited recovery of graphite.

High Energy Intensity: Massive fossil fuel or electricity consumption leads to a large carbon footprint.

Emissions Control: Requires sophisticated and expensive off-gas treatment systems to capture harmful fumes (HF, dioxins, particulates) and CO2.

Slag Management: The residual slag, containing unrecovered metals and potential contaminants, requires costly disposal or further treatment.

Lower Product Purity: Produces mixed metal alloys needing further refining.

Hydrometallurgy: Precision Through Chemistry

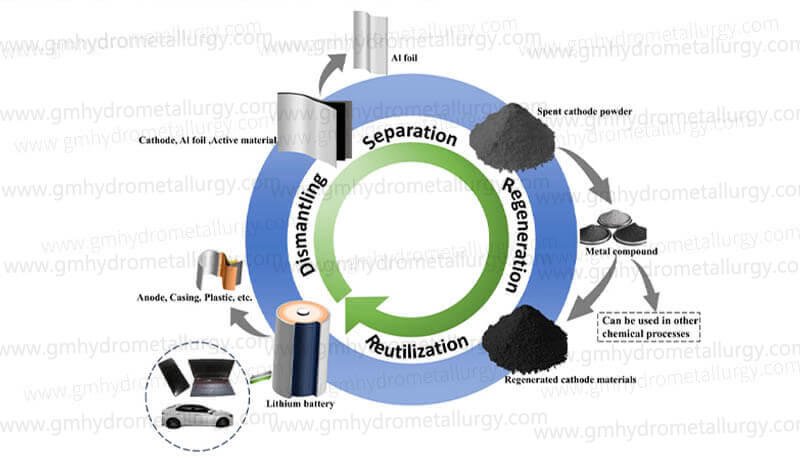

Hydrometallurgical recycling uses aqueous chemical solutions (acids or bases) at relatively low temperatures (<100°C typically) to selectively dissolve and recover target metals from battery “black mass” (crushed and separated active materials).

How it Works: Black mass undergoes leaching (dissolving metals). The resulting solution undergoes a series of purification steps (solvent extraction, ion exchange, precipitation) to isolate individual high-purity metal compounds (sulfates, hydroxides, carbonates) ready for direct reuse in new battery production.

Key Advantages:

High Recovery Rates: Achieves >95% recovery for critical metals like lithium, cobalt, nickel, manganese.

High Product Purity: Produces battery-grade materials suitable for direct cathode manufacturing.

Targeted Recovery: Precisely recovers specific valuable elements.

Lower Energy Consumption: Operates at near-ambient temperatures, significantly reducing carbon footprint.

Reduced Emissions: Minimal hazardous gas generation compared to pyrometallurgy.

Key Limitations & Challenges:

Feedstock Sensitivity: Requires consistent, well-segregated feed (black mass); performance varies with battery chemistry. Pre-treatment (dismantling, shredding, separation) is crucial.

Chemical Consumption & Management: Requires significant reagents and generates process residues (salts) that need responsible management or valorization.

Process Complexity: Involves multiple intricate steps (leaching, purification, precipitation).

Wastewater Treatment: Requires robust water treatment facilities.

Making the Strategic Choice: Hydrometallurgy vs Pyrometallurgy

The optimal path depends heavily on priorities:

Maximizing Resource Recovery & Purity

If recovering high-purity lithium, cobalt, nickel, and manganese for direct battery reuse is paramount (essential for a circular economy), hydrometallurgy is vastly superior.

Processing Mixed/Unknown Streams

For handling very heterogeneous or poorly sorted battery waste streams with lower purity demands, pyrometallurgy offers initial robustness, though with significant resource loss.

Environmental Footprint

Hydrometallurgy generally offers a significantly lower carbon footprint and avoids complex high-temperature emissions control.

Scalability & Cost

While pyrometallurgy has large-scale history in smelting, modern, modular hydrometallurgical plants are rapidly scaling and becoming more cost-competitive, especially considering the revenue from recovered high-purity materials. Innovations in closed-loop hydrometallurgy systems are reducing chemical consumption and waste.

The Future is Hybrid & Hydrometallurgical Innovation

While the debate continues, the trend is clear. Pure pyrometallurgy struggles to meet the high recovery rates and purity demands of modern battery recycling sustainably. Hydrometallurgy, despite its complexity, is the preferred route for high-value battery metal reclamation and closed-loop battery material production. Many modern facilities explore hybrid approaches (e.g., pyrometallurgy for initial volume reduction, followed by hydrometallurgy for high-purity recovery from slag or alloy).

Partnering for Sustainable Battery Recycling Solutions

Choosing between pyrometallurgical smelting and hydrometallurgical leaching processes shapes the economics and environmental impact of your battery black mass processing. Advanced hydrometallurgical recovery of lithium and cobalt is becoming the cornerstone of a truly sustainable and profitable urban mining operation for end-of-life EV battery treatment.

Understanding the critical hydrometallurgy vs pyrometallurgy battery recycling distinction empowers you to invest in technologies that maximize resource efficiency, minimize environmental harm, and secure the critical materials needed for our electrified future.