For industrial businesses and investors, the decision to set up a lead smelting plant is a significant step towards securing a reliable supply of this crucial non-ferrous metal. Whether you’re aiming to process recycled lead-acid batteries or primary lead concentrates, a successful operation hinges on strategic decisions made from the outset.

Key Considerations Before You Set Up Lead Smelting Plant

Raw Material Analysis

Before breaking ground, thorough feasibility analysis is critical. You must assess your feedstock sources (primary lead concentrates or secondary scrap).

Market Demand Analysis

You must analyze market demand for refined lead, understand regional competition, and develop a robust financial model.

Infrastructure Costs

Crucially, this plan must account for the substantial capital investment required for plant infrastructure, specialized machinery like a high-capacity lead smelting furnace, and the ongoing costs of the lead refining process.

Navigating Environmental

understand local and international environmental regulations, and secure the necessary permits.

Site Selection

The plant’s location should balance proximity to raw materials, energy supply, transportation networks, and environmental safety buffers.

Choosing the Right Lead Smelting Plant Manufacturer

Your choice of a lead smelting plant manufacturer is arguably the most crucial decision. Guanma Machinery lead smelting rotary furnace manufacturer does not just supply equipment; they provide end-to-end solutions.

Customizable Capacity

Lead smelting equipment capacity can be customized according to requirements: 5t/furnace, 10t/furnace, 20t/furnace, 40t/furnace, 60t/furnace.

Selection of Smelting Technology

Guanma machinery should guide you on the optimal technology (e.g., Isasmelt, QSL, or traditional blast furnace) based on your raw material and capacity goals.

Comprehensive Services

Guanma machinery provide comprehensive services, including installation, commissioning, and operator training.

Understanding the Lead Smelting and Refining Process

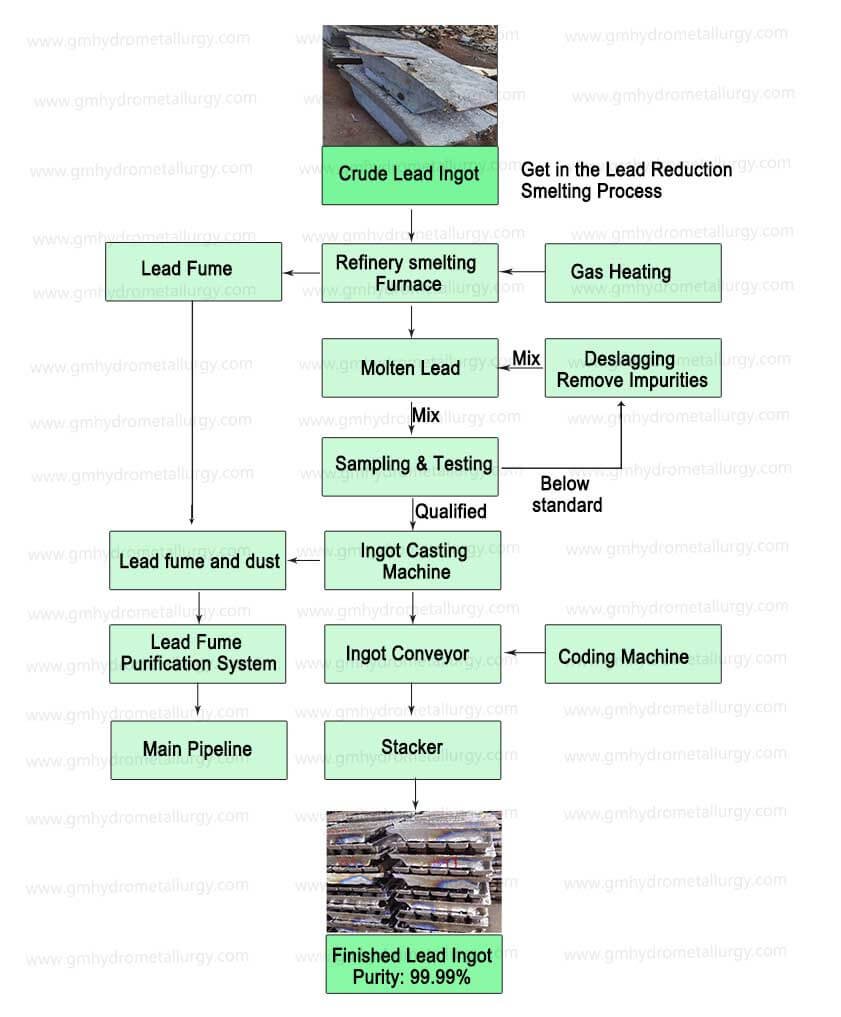

The core of your operation is the lead smelting and refining process. It typically involves two main stages.

Lead Smelting Process

First, smelting: prepared feed is charged into a lead melting rotary furnace where it is heated to high temperatures. This causes chemical reactions that separate crude (bullion) lead from waste material (slag).

Lead Refining Process

Second, refining: the crude lead undergoes lead refining furnace to remove impurities like copper, tin, arsenic, and silver through a series of controlled thermal and chemical treatments, resulting in high-purity commercial lead (often 99.97%+ pure).

Core Equipment Spotlight: The Lead Smelter and Furnace

At the heart of the facility is the lead smelter, an integrated system designed for efficiency and emission control. The choice of lead melting furnace—whether it’s a rotary, reverberatory, or modern top-submerged lance furnace—directly impacts fuel efficiency, metal recovery rate, and environmental performance.

The Critical Stage of Lead Refining

Lead refining transforms crude lead into a marketable product. This multi-step process includes drossing, sulfurization, and final pyrometallurgical or electrolytic refining. Each step targets specific impurities.

Ready to Build Your Lead Smelting Facility?

Setting up a successful lead plant requires expertise, precision engineering, and reliable technology. From initial concept to final commissioning, partnering with an experienced supplier makes all the difference.

Contact us today to discuss your project specifics. guanma machinery team of experts is ready to provide detailed solutions to ensure your new lead smelting plant is efficient, compliant, and profitable.