For any gold refiner, from a large-scale operation to a specialized high recovery gold refiner, the ultimate measure of success and profitability is the gold recovery rate.

Industry Standards & Calculation: Know Your Baseline

The industry-standard benchmark for gold refining recovery rate typically falls between 95% and 99.5%. High-end operations consistently target the upper limit. To track improvement, you must calculate your rate accurately:

Recovery Rate (%) = (Weight of Pure Gold Output / Total Gold Content in Feed Material) * 100

Precise assay of your feedstock is non-negotiable. Establishing this baseline is the first step in identifying losses and targeting specific areas for improvement with your equipment.

Core Factors Impacting Your Recovery Rate

Equipment Type & Design

The choice between traditional chemical reactors, advanced electrolytic systems, or integrated high recovery gold refiner modules dictates the maximum potential recovery. Modern, closed-loop systems minimize fumes and spillage.

Feedstock Preparation

Inadequate crushing, grinding, or incineration (for e-scrap) locks gold within matrices. Uniform particle size is critical for complete chemical reaction.

Critical Operational Parameters

Temperature, pH level, reagent concentration (e.g., aqua regia ratio), and reaction time are not set-and-forget. Suboptimal settings lead to incomplete dissolution or premature precipitation.

Filtration & Transfer Efficiency

This is where major physical losses happen. Poor filter media, rushed transfers, or inadequate rinsing of slimes can trap significant amounts of gold.

Gold Refining Equipment Tuning & Optimization Techniques

Your Gold Refining Equipment is highly tunable. Implement these direct adjustments:

Parameter Precision

Use sensors and controllers to maintain optimal temperature (±2°C) and pH. For aqua regia refining, meticulously control the nitric acid drip rate to dissolve all metals without creating excessive fumes that carry gold values.

Module-Specific Optimization

In electrolytic cells (Wohlwill), fine-tune current density, electrolyte circulation, and cathode surface area to produce smooth, dense gold crystal growth, minimizing powder losses. For chemical systems, implement multi-stage precipitation and settling tanks.

The “Rinse Cycle” Protocol

Design a rigorous, multi-stage rinsing protocol for every filter cake and vessel. Use clean acidified water and combine rinse solutions with the next batch’s primary solution to ensure no gold is washed down the drain.

Tailored Methods for Different Feedstock Types

Crude Gold (Dore Bar)

Control the silver content before electrolysis. Optimal silver levels (typically 5-10%) help produce a firm anode slime that is easily contained and processed, preventing slime losses.

Gold-Bearing Scrap (Jewelry, Dental)

Remove all organic and base metal contaminants before the primary refining cycle. Use a dedicated inquartation and parting step for karat gold to ensure complete separation and digestion.

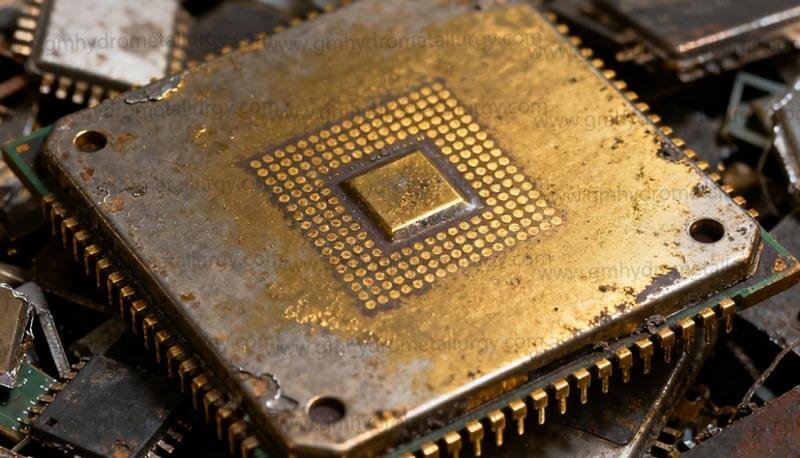

Electronic Gold (E-Waste)

Ensure complete incineration of PCBs to carbon-free ash. For leaching processes, optimize aeration, agitation, and leach time specific to your milled material.

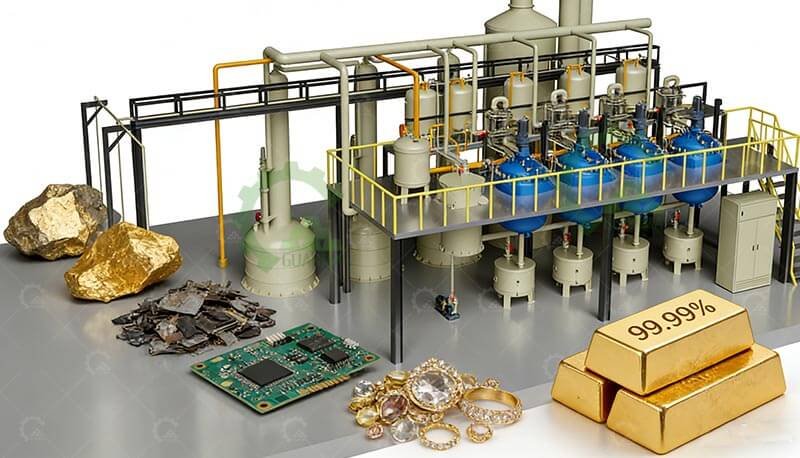

Core Configuration of a High-Recovery System

To consistently achieve >99% recovery, your equipment setup must include:

Closed-Vessel Reaction System: Prevents atmospheric release of gold-bearing vapors.

Advanced Filtration Cascade: A sequence of filters and a secure filter press to extract every particle of gold mud.

Integrated Scrubber & Condensing Unit: Captures and returns volatilized gold values back into the reaction cycle.

Precision Instrumentation: Automated dosing pumps, digital pH/temperature controllers, and flow meters for repeatable, optimal process conditions.

Comprehensive Solution Management: Zero-discharge design with holding tanks for all waste water, allowing for final gold stripping via ion exchange or cementation.

Improving your gold recovery rate is a deliberate process of measurement, analysis, and precise adjustment of your Gold Refining Equipment. Investing in a well-configured high recovery gold refiner and adhering to these operational disciplines is the most direct path to maximizing your yield and boosting your bottom line.