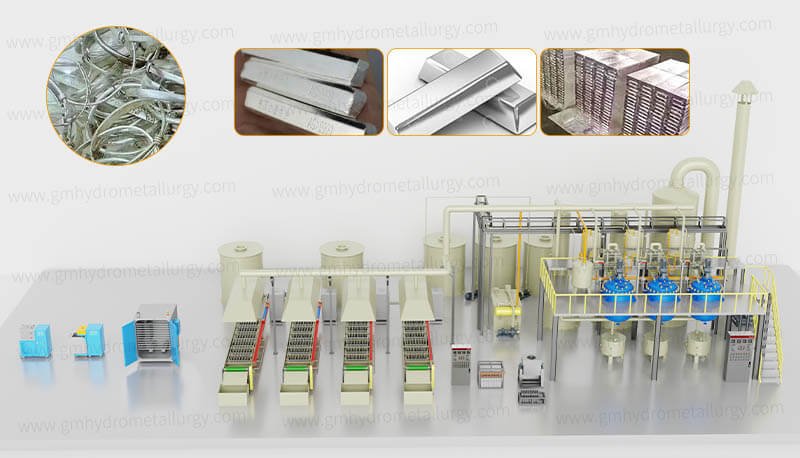

As Silver Electrolysis Refining Machine Manufacturers, Guanma Machinery stands as your trusted engineering partner. We specialize in delivering advanced electrolytic silver refining machine systems designed to process your specific raw materials, significantly boost your profitability.

What Raw Materials Can Our Systems Process?

A common question we encounter is, “what is refining silver” in a practical sense? It’s the process of transforming impure silver materials into high-purity, market-ready metal. Our silver electrolysis refining machine is engineered to handle a wide range of source materials, providing a versatile solution for your silver refinery plant.

Key inputs include:

Silver anode from primary smelting (e.g., from silver ore)

Silver-rich anode slimes

Jewelry and silverware scraps

Silver-coated materials and electronic waste concentrates

Silver residues from photographic and electronic industries

This flexibility ensures that no matter your starting point, our technology can be tailored to maximize your silver recovery.

Client Needs

We understand that your search for a silver refining machine price is about more than just initial cost; it’s about total value and return on investment. Our clients approach us with several critical needs:

Achieving Consistently High Purity

The end goal is to produce 99.99% (or higher) pure silver that commands the best market price.

Controlling Operational Expenditure

Managing the silver refining cost is paramount, encompassing energy consumption, labor, and chemical usage.

Ensuring Operational Safety and Environmental Compliance

The refining silver process must be safe for operators and environmentally sound.

Silver Refinery Solution

Inconsistent Purity and Yield

Our Solution: Our proprietary cell design and optimized electrolyte management system ensure a stable and highly efficient silver refinery process. Minimizes silver loss in the anode slimes.

High Operational and Refining Costs

Our Solution: While the initial silver refinery machine price is a key consideration, our systems are built for long-term economy. They feature high energy efficiency, automated controls that reduce labor dependency, and a closed-loop electrolyte system that minimizes chemical consumption. This holistic approach drastically lowers your long-term silver refining cost.

Complex and Hazardous Processes

Our Solution: We have simplified and safeguarded the refining silver process. Our machines are designed with integrated fume extraction and safety interlocks, protecting your workforce and ensuring your plant meets environmental standards. This transforms a traditionally complex operation into a streamlined, manageable process.

When you evaluate the silver refining machine price in China, Guanma Machinery offer more than just machines—we provide turnkey support, from initial design to on-site installation and staff training. Contact Silver Electrolysis Refining Machine Manufacturers today to discuss your specific requirements and receive a detailed proposal.