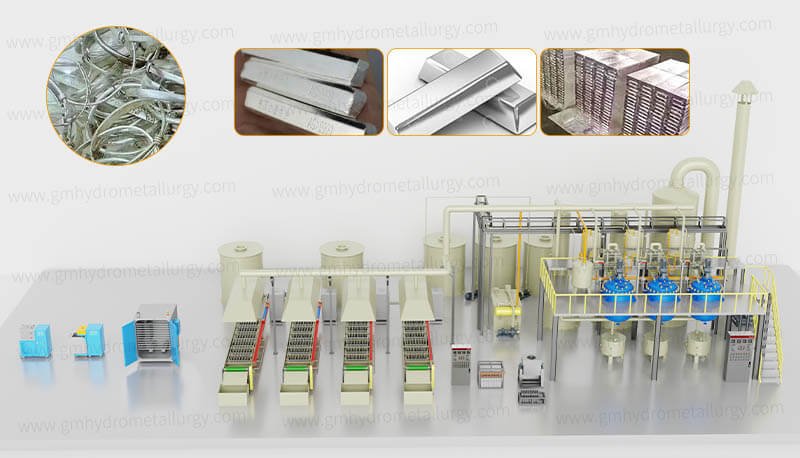

Facing the challenge of recovering high-value silver from your spent catalysts efficiently and profitably? This is where our specialized 100kg/day Silver Catalyst Refining Unit delivers a transformative solution.

Beyond Basic Recovery: Precision Refining for Maximum Yield & Purity

Standard recovery methods often fall short, leaving significant value trapped or yielding subpar silver requiring further costly processing. Our turnkey 100kg/day refining unit is engineered specifically for high-efficiency silver catalyst reclamation, focusing on:

1. Unmatched Input Handling

Designed for optimal processing of input material like used silver granules boasting 99.9999% Ag (6N purity) commonly found in high-grade catalysts. The system efficiently liberates the silver matrix.

2. Advanced Electrolytic Refining

The core of the unit utilizes cutting-edge electrolysis technology. This process meticulously separates pure silver from contaminants (base metals, carbon supports, silica, alumina), consistently achieving output purity exceeding 99.99% (4N+) – ready for direct reuse in catalyst manufacturing or high-value markets.

3. High-Capacity, Optimized Output

Process 100kg of spent catalyst material per day reliably. This scalable capacity is ideal for medium to large-scale industrial operations seeking predictable, continuous throughput without massive infrastructure.

4. Closed-Loop, Zero-Waste Philosophy

We integrate state-of-the-art effluent treatment and tailings management. Recover residual traces and neutralize harmful byproducts, ensuring environmental compliance and moving towards true sustainable silver refining.

5. Maximized ROI & Reduced Downtime

Engineered for operator safety (automated controls, fume extraction) and minimal maintenance. Recover near-theoretical yield of your valuable silver asset, significantly lowering your net catalyst costs and boosting profitability.

Why Choose Our 100kg/day Unit Over Generic Solutions?

Precision for High-Grade Input

Specifically calibrated for high-purity spent granules (like your 99.9999% Ag material), maximizing yield where generic units struggle.

Space-Efficient & Modular

Requires a surprisingly compact footprint. Designed as a modular refining skid, allowing for easier installation and potential future expansion.

Focus on Operational Economics

Low chemical consumption thanks to efficient processes and potential reagent recycling loops. Reduced energy requirements per kg of silver recovered compared to older technologies.

Data-Driven Process Control

Advanced monitoring ensures consistent purity and optimal efficiency, providing traceability crucial for quality assurance.

Solutions for Your Critical Concerns:

Solving “cost-effective in-house silver catalyst recovery”.

Addressing “meeting strict silver purity specs for catalyst reuse”.

Enabling “scalable precious metal refining capacity” without massive capital outlay.

Providing “sustainable, closed-loop silver refining solutions”.

Offering “safe and automated silver recovery from spent catalysts”.

Facilitating “high-yield silver reclamation from high-purity granules” (like your 99.9999% Ag input).

Stop Losing Value in Your Spent Catalyst Streams.

Our 100kg/day Silver Catalyst Refining Unit isn’t just equipment; it’s your strategic partner in unlocking the full, pure potential of your silver assets. Move beyond basic recovery to precision refining that delivers maximum financial return, operational safety, and environmental responsibility.

Ready to transform your spent catalyst liability into a pure silver profit center?

Contact us today for a detailed technical proposal and discover how our optimized 100kg/day solution can revolutionize your recovery process. Request a Scrap Audit & ROI Calculation!