Investing in the right gold silver platinum palladium and rhodium extraction equipment is the most critical decision for any business in the precious metals recovery and refining industry. The efficiency, yield, and safety of your operations directly depend on the technology you employ.

Understanding Your Raw Materials and Goals

Before evaluating machinery, you must first define your primary feedstock. The choice of precious metal refining machinery is heavily influenced by the type of material you process:

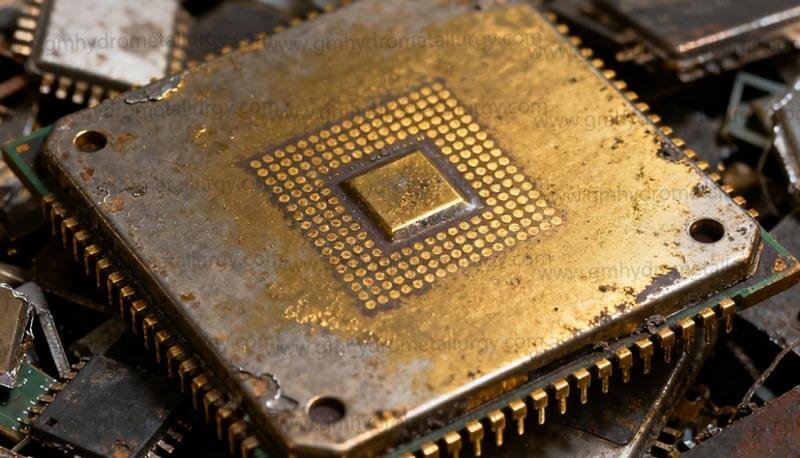

Electronic Waste (E-Waste)

PCBs, chips, and connectors contain gold, silver, palladium, and trace amounts of rhodium. This often requires shredding, crushing, and sophisticated chemical separation.

Catalytic Converters

The primary source for platinum, palladium, and rhodium (PGMs). Extraction requires specialized platinum group metals (PGM) refining equipment capable of handling ceramic or metallic substrates.

Jewelry Scrap and Mine Tailings

Rich in gold and silver, often needing smelting and electrolytic processes.

Industrial Catalysts and Chemicals

May contain various PGMs.

Your operational goals—whether large-scale industrial processing or smaller, specialized recovery—will determine the required capacity and level of automation.

Key Types of Extraction and Refining Equipment

A complete recovery line is not a single machine but an integrated system. Here’s a breakdown of core components:

1. Pre-Treatment and Preparation Equipment

This is the first and crucial step. It includes:

Crushers, Shredders, and Mills: To reduce the physical size of e-waste or catalytic converter honeycombs, increasing surface area for chemical reactions.

Classification and Separation Systems: Like air classifiers or magnetic separators to isolate metallic and non-metallic components.

2. Pyrometallurgical Systems (Smelting)

Induction Melting Furnaces: Used to melt scrap with fluxes to separate precious metals from slag. A precious metal extraction furnace is essential for recovering gold and silver from jewelry scrap or concentrated materials.

Arc Furnaces: Used for larger-scale operations, particularly in PGM recovery.

3. Hydrometallurgical Systems (Chemical Leaching)

This is the core of modern refining, especially for complex materials like e-waste.

Leaching Reactors: Tanks where material is mixed with chemical solutions to dissolve the target metals. Advanced reactors are corrosion-resistant and computer-controlled for optimal efficiency.

Filtration and Separation Units: Used to separate the pregnant solution (containing dissolved metals) from the solid waste.

4. Electrolytic Recovery Systems (Electrolysis)

Electro-winning Cells: For extracting pure metal from the pregnant solution by passing an electric current through it. This is standard for high-purity gold and silver recovery.

Electro-refining Cells: Further purifies already extracted metal, producing high-purity bars (e.g., 99.99% gold).

5. PGM-Specific Refining Equipment

Recovering platinum, palladium, and rhodium requires additional, precise steps like:

Distillation and Precipitation Units: To separate individual PGMs from complex chloride solutions.

Calcination Furnaces: To convert purified compounds into pure metal sponge.

How to Choose the Right Equipment Supplier

Selecting a partner is as important as selecting the technology. Consider these factors:

Technical Expertise and Experience

Choose a supplier of catalytic converter processing plants or e-waste recycling systems with a proven track record. Request case studies and client references.

Technology and Process Support

The best suppliers offer not just machines, but a complete process flow sheet tailored to your raw materials. Ensure they provide robust chemical processing equipment for precious metals and understand the chemistry involved.

Safety and Environmental Compliance

The equipment must be designed to contain emissions, recover chemicals, and produce effluent that can be treated to meet strict environmental regulations.

After-Sales Service and Training

Verify the availability of installation, commissioning, operational training, and spare parts support. Your operation cannot afford prolonged downtime.

Investing in Efficiency and Yield

The right gold silver platinum palladium and rhodium extraction equipment is a significant investment that defines your business’s profitability and sustainability. By carefully assessing your feedstock, understanding the available technologies, and partnering with an experienced and supportive manufacturer, you can build a recovery operation that is efficient, safe, and highly profitable for years to come.

Ready to upgrade your recovery process? Contact our experts today for a free consultation and system design tailored to your specific material stream and output goals.