Gold refining is a crucial process that transforms gold into standardized products. Gold refining enterprises aim to build their brand reputation, enhance corporate image, and improve both product qualification rates and gold recovery efficiency.

What is Gold Refining?

Gold refining refers to the process of removing impurities from gold mud or raw gold to ensure that the final gold products meet the quality standards required for gold trading.

Gold Refining Process Methods

Currently, the primary refining methods include electrolytic refining and solvent extraction refining.

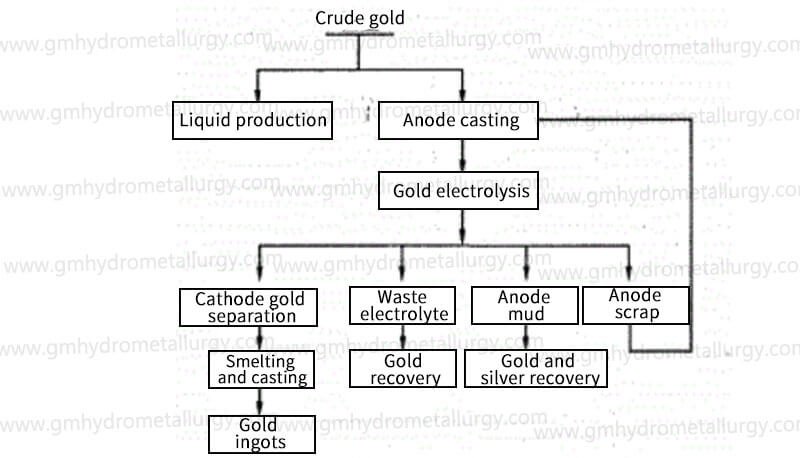

01 Electrolytic Refining

The electrolytic refining process has a long history in gold production and is widely used in the non-ferrous metals industry for gold purification. Today, over 90% of refining enterprises utilize electrolytic refining to produce gold.

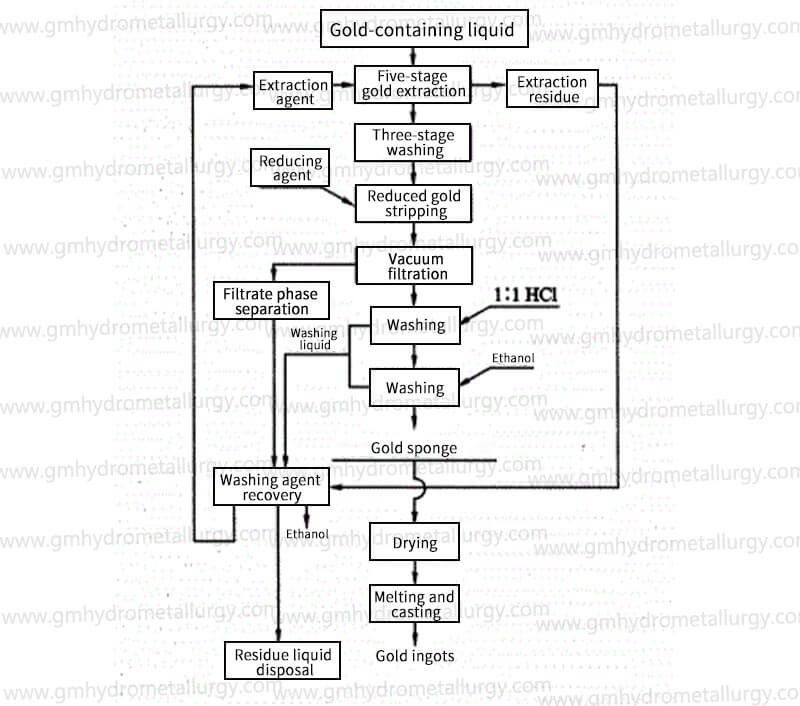

02 Solvent Extraction Refining

Approximately 5% of gold refining companies currently use solvent extraction refining to purify gold. In this process, raw materials are dissolved through chlorination, and an extractant is used to separate AuCl from the chloride solution, achieving the separation of gold from other impurities.

The above explains the key differences between electrolytic refining and solvent extraction refining in gold refining. For more detailed information, feel free to contact Guanma Machinery for tailored gold refining solutions!