Why Gold Refining Matters Today?

With natural gold resources becoming harder and more expensive to mine, refining gold from scrap has become a smart and sustainable alternative.

The Growing Value of Scrap Gold

Scrap gold is everywhere: broken jewelry, circuit boards, connectors, and even dental waste. The trick is knowing how to extract it efficiently and safely.

Understanding Scrap Gold

Before refining begins, it’s crucial to understand what scrap gold actually is.

Common Sources of Scrap Gold

Electronic Waste

Printed circuit boards, CPUs, connectors, and chips are rich in gold due to its excellent conductivity and corrosion resistance. E-waste recycling has become one of the fastest-growing sources of recoverable gold.

Jewelry and Industrial Scrap

Old rings, necklaces, gold-plated parts, and manufacturing leftovers often contain gold alloys that can be refined back to high purity.

Gold Content and Purity Challenges

Scrap gold is rarely pure. It’s mixed with copper, silver, nickel, and other metals. That’s why a complete gold refining solution is essential—to separate gold cleanly without unnecessary loss.

Gold Refining Methods

Physical vs Chemical Refining Methods

Physical methods like melting and gravity separation are often used in pre-treatment. Chemical refining, on the other hand, is where real purification happens—using controlled reactions to dissolve and recover gold selectively.

Key Principles of Gold Separation

Gold doesn’t react easily, which is both a blessing and a challenge. Gold refining systems exploit differences in chemical reactivity, solubility, and electrochemical behavior to isolate gold from other metals.

Complete Gold Refining Solution

A complete gold refining solution isn’t just one machine. It’s an integrated system that handles everything—from raw scrap input to high-purity gold output.

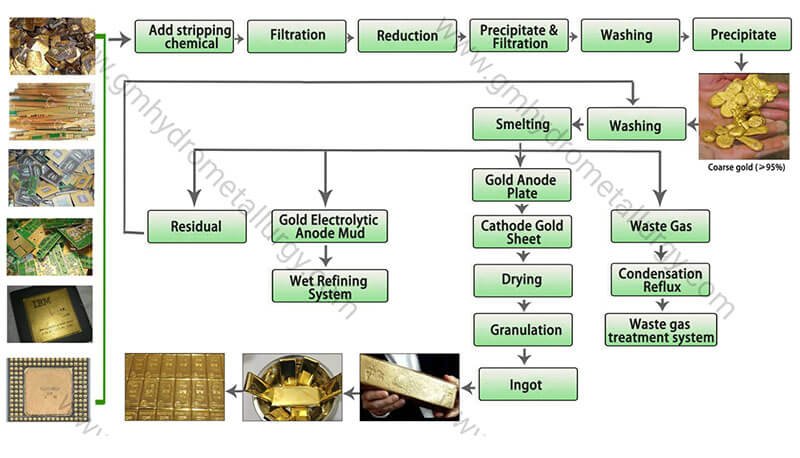

End-to-End Refining Workflow

From sorting and crushing scrap to chemical processing, filtration, and final casting, a complete solution ensures every stage works together smoothly.

Step-by-Step Gold Refining Process

Pre-Treatment and Crushing

Scrap materials are first sorted and crushed to increase surface area. This step improves reaction efficiency and reduces processing time.

Smelting and Melting

Melting helps remove plastics and base impurities while forming a metal concentrate that’s easier to refine chemically.

Chemical Leaching and Dissolution

Gold is dissolved using controlled chemical solutions. This step separates gold from unwanted metals at a molecular level.

Gold Precipitation and Recovery

Once dissolved, gold is selectively precipitated back into solid form. It’s like pulling pure gold out of a chemical soup.

Final Purification and Casting

The recovered gold is melted again and cast into bars, grains, or custom shapes—often reaching 99.99% purity.

Gold Refining Equipment Overview

Gold Melting Furnace

High-temperature furnaces ensure uniform melting and stable operation, forming the backbone of any refining setup.

Chemical Reactors and Tanks

These vessels handle leaching and precipitation reactions safely and efficiently.

Filtration and Precipitation Systems

Advanced filtration ensures no gold is lost during separation, maximizing recovery rates.

Gold Refining Machine Automation

Modern systems use automation to control temperature, chemical dosing, and timing—reducing human error and improving consistency.

Environmental and Safety Considerations

Emission Control and Waste Treatment

A responsible gold refining solution includes exhaust gas treatment and wastewater recycling, keeping operations compliant and eco-friendly.

Operator Safety and Compliance

Closed systems, corrosion-resistant materials, and safety interlocks protect workers from chemical exposure.

A complete gold refining solution transforms waste into wealth, delivering high recovery, consistent purity, and sustainable profits.

If you are interested in starting a gold scrap refining business, please contact Guanma Machinery for quotes and solutions!