Understanding the electrolytic refining process is essential, as it is the industry standard for producing the purest forms of conductive metals like copper, nickel, gold, and silver.

What is Electrolytic Refining?

Electrolytic refining is an electrochemical process used to purify impure metals. It utilizes the principle of electrolysis, where an electric current is passed through a solution to drive a non-spontaneous chemical reaction. The primary objective is to extract pure metal from a crude anode, leaving the impurities behind.

A Step-by-Step Breakdown of the Electrolytic Refining Process

The process is most commonly associated with copper, but the fundamental steps apply to other metals. Here’s a detailed look at how it works:

1. Preparation of the Anode and Cathode

The Anode

A thick slab of the impure metal (e.g., ~99% pure copper from smelting) is cast and serves as the positive anode. This anode contains valuable metal but also includes impurities like gold, silver, platinum, selenium, tellurium, and base metals.

The Cathode

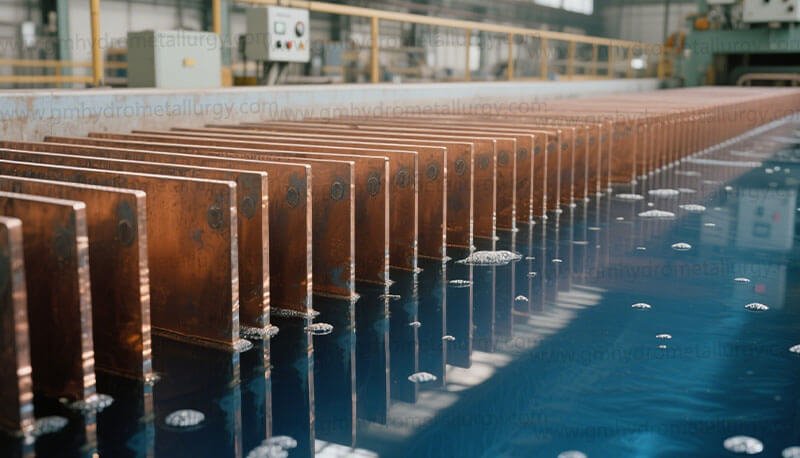

A thin starter sheet of very pure metal (~99.99% pure) or, in modern plants, a permanent stainless steel blank is used as the negative cathode. This is where the pure metal will be deposited.

2. The Electrolyte Solution

A suitable aqueous acid solution is prepared in an electrolytic tank. Forcopper electrolytic refining, the solution is typically copper sulfate (CuSO₄) acidified with sulfuric acid (H₂SO₄). This solution contains a high concentration of Cu²⁺ ions, which are crucial for the transfer of metal from the anode to the cathode.

3. The Electrolysis Reaction

When a direct current (DC) is passed through the circuit:

At the Anode (Oxidation)

The impure metal anode undergoes oxidation. Metal atoms lose electrons and dissolve into the electrolyte as positive ions. For copper: Cu (impure) → Cu²⁺ + 2e⁻.

At the Cathode (Reduction)

The metal ions (Cu²⁺) from the electrolyte gain electrons and are reduced. They are deposited as pure, solid metal onto the cathode sheet. For copper: Cu²⁺ + 2e⁻ → Cu (pure).

4. The Role of Impurities

This is the most critical aspect of the electrolytic purification of metals:

Less Active Impurities (Noble Metals)

Precious metals like gold, silver, and platinum do not dissolve as easily as the base metal. They are not oxidized and fall to the bottom of the tank as a sludge called anode slime. This slime is a valuable by-product collected for further processing to recover these precious metals.

More Active Impurities (Base Metals)

Metals like iron and zinc are more reactive and do dissolve into the electrolyte. However, they remain in solution because their reduction potential is lower than that of the primary metal (e.g., copper). They will not deposit on the cathode unless the voltage is drastically altered, thus ensuring the cathode remains pure.

5. Harvesting the Cathodes

After a cycle lasting several days, the cathodes are removed. The pure metal deposits, now weighing hundreds of pounds, are stripped off. These cathodes are the final product, often 99.99% pure metal, ready to be melted and cast into shapes like wires, cables, or cathodes for sale.

Key Advantages of Electrolytically Refined Metals

Why should you specify metals produced through this process?

Exceptional Purity (>99.99%)

Essential for high-conductivity applications in electronics and electrical wiring.

Recovery of Precious Metals

The process is economically viable as it efficiently recovers valuable by-products.

Consistent Quality

The controlled nature of electrolysis ensures a uniform and reliable product batch after batch.

Partner with a Knowledgeable Supplier

When sourcing, partner with a supplier who understands the principles of electrolytic refining and can provide certified, high-purity copper cathodes, nickel pellets, or other refined metals. Their expertise ensures you receive a product that meets your exact technical specifications and quality standards.

Contact us today to discuss your requirements for electrolytically refined metals and experience the difference that purity makes.