Copper Electrorefining

Copper electrorefining is a vital industrial process used to purify blister copper—produced via pyrometallurgical refining—with a copper content of 99.0% to 99.8%. Despite its high copper grade, the remaining impurities (0.2%–1.0%) make it unsuitable for many industrial applications.

Electrorefining not significantly improves the purity and performance of copper but also allows for the recovery of valuable metals, including rare and precious metals (such as Au, Ag, Se, and Te) and platinum group metals. The output, known as cathode copper or electrolytic copper, boasts exceptional purity levels.

How Copper Electrorefining Works

Composition of Anodes and Cathodes

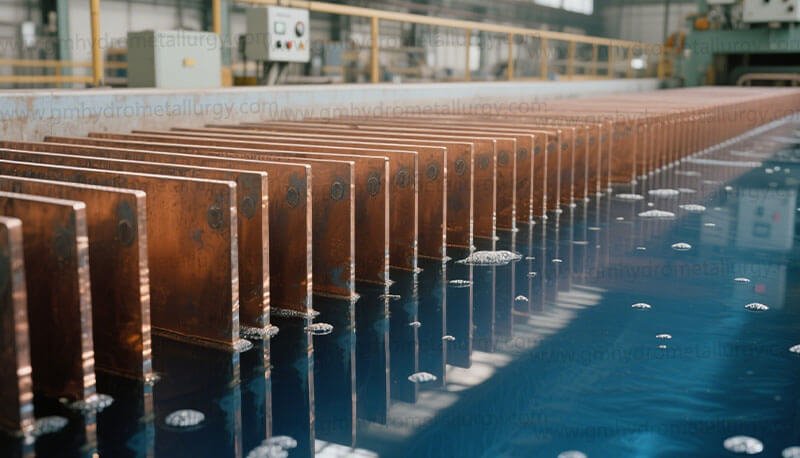

In the copper electrolytic refining process, anodes are cast from blister copper obtained through fire refining. Cathodes are thin starter sheets made of highly pure copper. These are placed alternately in electrolytic tanks filled with an acidic solution containing copper sulfate (CuSO₄) and sulfuric acid (H₂SO₄).

Electrochemical Reactions During Refining

When electric current is applied, copper and less noble metals dissolve from the anode. Copper ions migrate through the electrolyte and are preferentially deposited onto the cathode due to their favorable electrochemical properties. This selective deposition is key to producing high-purity copper.

Separation and Recovery of Impurities

Formation of Anode Slime

Metallic impurities with less electrochemical activity than copper, such as gold, silver, selenium, and tellurium, do not dissolve during electrolysis. Instead, they accumulate at the bottom of the electrolytic cell as anode slime, which is later collected for valuable metal recovery.

Dissolved Impurities in the Electrolyte

More active impurities like iron, nickel, and zinc dissolve into the electrolyte but do not deposit on the cathode under controlled conditions. Regular purification of the electrolyte is conducted to maintain its composition and ensure product quality.

Applications and Benefits of Electrolytic Copper

The high-purity cathode copper produced through this process is ideal for applications in electrical wiring, electronics, and advanced industrial components. Additionally, the recovery of precious and rare metals adds significant economic value to the process.

Thank you for learning about copper electrorefining. Contact guanma machinery today to discuss your needs and receive a professional copper electrorefining solution tailored to your operation!