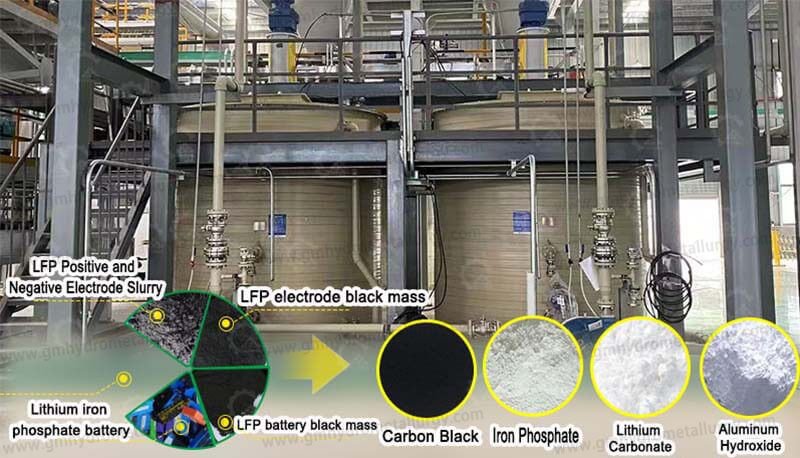

As China’s LFP battery black mass hydrometallurgical recycling machine supplier, Guanma Machinery specialize in providing cutting-edge technology designed to maximize your recovery rates, purity, and operational efficiency. We understand your challenges and deliver tailored systems to overcome them.

Solving Your Critical LFP & NMC Black Mass Recycling Challenges

Processing spent lithium-ion battery black mass demands precision and advanced technology. Generic solutions often fall short, leading to subpar recovery, purity issues, and environmental concerns. Our expertise as a dedicated hydrometallurgical recycling equipment manufacturer directly addresses these pain points:

Navigating Diverse Feedstock Complexity

Understanding Your Black Mass

We know your black mass composition varies – primarily graphite, lithium iron phosphate (LFP), or mixed nickel-manganese-cobalt oxides (NMC), plus binders, electrolytes, and copper/aluminum foils. Our systems are engineered to handle this complex LFP black mass composition effectively.

Flexible Pre-Treatment Integration

Whether you use mechanical separation, pyrolysis, or other methods, our hydrometallurgical line seamlessly integrates to process the resulting powder or concentrate.

Matching Precise Processing Capacity

Custom-Built for Your Scale

There’s no one-size-fits-all. We design and build modular plants ranging from compact pilot-scale units (500 kg/day) to large industrial facilities (50+ tons/day) for continuous black mass hydrometallurgical processing.

Optimized Throughput & Efficiency

Our focus is on maximizing your plant uptime and metal yield per unit of input, ensuring your operation is profitable.

Achieving High-Purity, Marketable End Products

Superior Recovery Rates

Our advanced processes consistently achieve >98% lithium leaching efficiency and >95% recovery of valuable metals like nickel, cobalt, and manganese from NMC sources.

Battery-Grade Outputs

We deliver technology that produces high-purity lithium carbonate (Li2CO3), suitable for direct reuse in new battery cathode production. For NMC, expect high-purity sulfate or hydroxide salts of nickel, cobalt, and manganese.

Comprehensive Recovery

We ensure efficient recovery of graphite and other potential by-products, minimizing waste streams.

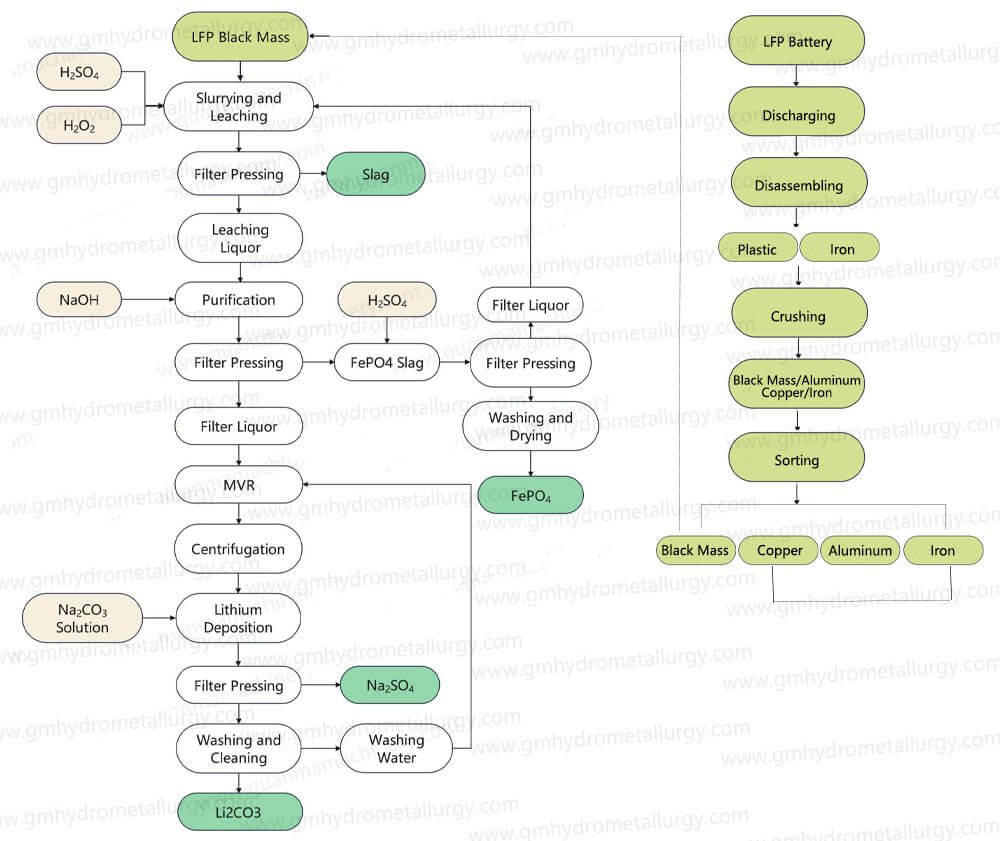

Our Advanced Hydrometallurgical Recycling Workflow

As your trusted LFP black mass hydrometallurgical processing plant supplier, we provide technology centered around a sophisticated, often closed-loop, chemical process:

1. Selective Leaching (H2SO4 based)

Our optimized leaching reactors use controlled sulfuric acid concentration, temperature (typically 50-90°C), and precise redox potential to selectively dissolve lithium, nickel, cobalt, and manganese from the black mass into solution, while minimizing iron phosphate dissolution from LFP.

Advanced mixing and reaction kinetics ensure maximum extraction efficiency.

2. Sophisticated Solution Purification

Impurity Removal: Multi-stage precipitation and filtration steps meticulously remove impurities like iron, aluminum, copper, and residual phosphates, achieving the high-purity battery metal solutions essential for premium product recovery.

Selective Precipitation: For mixed NMC/LFP streams, we implement selective precipitation techniques to isolate specific metals effectively.

3. Precise Metal Recovery

Lithium Carbonation: Purified lithium solution reacts with sodium carbonate (Na2CO3) to precipitate high-purity battery-grade lithium carbonate (Li2CO3), ready for the cathode supply chain.

NMC Metal Salt Precipitation: Nickel, cobalt, and manganese are precipitated as high-purity individual sulfates or hydroxides (NiSO4, CoSO4, MnSO4, etc.) using controlled pH adjustment and precipitation agents.

4. Closed-Loop Efficiency & Waste Minimization

Acid Regeneration: Our systems often incorporate acid recovery units, significantly reducing fresh acid consumption and waste generation – a key feature of our closed-loop hydrometallurgical process.

Comprehensive Effluent Treatment: Integrated wastewater treatment ensures all effluents meet stringent environmental standards before discharge or reuse. Solid residues are stabilized for safe disposal or potential utilization (e.g., construction materials).

Why Partner with China’s LFP Battery Recycling Machine Supplier?

Unmatched Process Expertise: Deep specialization in the unique chemistry of LFP battery black mass hydrometallurgical recycling.

Proven Technology & Reliability: Robust, automated systems built for continuous industrial operation with high availability.

Maximized ROI: Engineered for the highest metal recovery rates (>95% Li, >98% Co/Ni/Mn), lowest reagent consumption, and minimized waste disposal costs.

Sustainable by Design: Our closed-loop acid regeneration system and near-zero liquid discharge options set the standard for environmentally responsible recycling.

End-to-End Support: From feasibility studies and custom engineering to installation, commissioning, training, and ongoing technical service.

Contact China’s Hydrometallurgical Recycling Machine Supplier Today!

Partner with the specialist LFP battery black mass hydrometallurgical recycling machine supplier dedicated to solving your specific challenges and maximizing the value from your spent battery resources.

Ready to transform your battery recycling operation? Contact us now!