Finding a truly reliable rotary furnace supplier for lead smelting is critical for your bottom line and operational success. Look no further than Guanma Machinery – recognized as China’s best lead smelting rotary furnace supplier.

Why Guanma Stands Apart as Your Premier Lead Smelting Partner

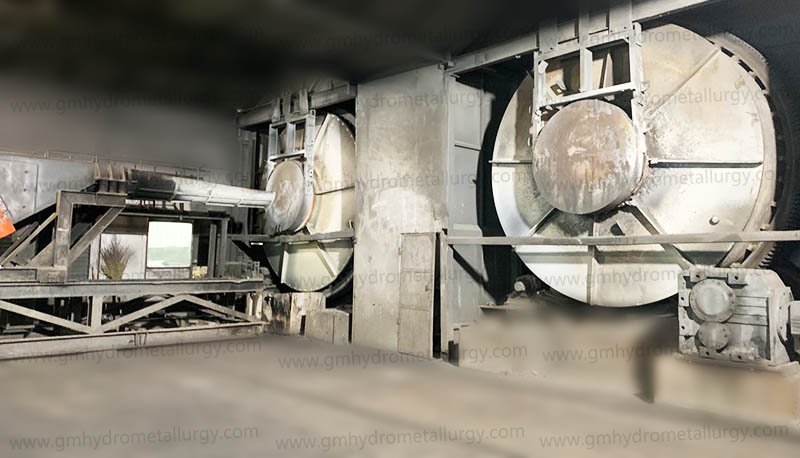

We understand your core needs: maximizing metal recovery, minimizing operational costs (especially energy), ensuring equipment longevity, and maintaining environmental compliance. Guanma Machinery designs and builds rotary furnaces specifically engineered to excel in demanding lead smelting and refining applications:

1. Unmatched Efficiency & Energy Savings

Our furnaces feature advanced refractory lining designs and optimized combustion systems, achieving thermal efficiencies exceeding 85%. This translates directly to significant reductions in fuel consumption for lead processing – often cutting energy costs by 30% or more compared to outdated models. Experience faster melting cycles and higher throughput.

2. Superior Durability for Harsh Environments

Lead smelting is corrosive and abrasive. Guanma furnaces utilize premium-grade, high-alumina refractory bricks and specialized alloy steels in critical areas like the furnace shell and charging/discharge mechanisms. This robust construction delivers extended service life for lead rotary kilns, drastically reducing maintenance frequency and unexpected shutdown costs.

3. Optimized Lead Recovery & Purity

Precise temperature control systems and optimal barrel rotation ensure thorough mixing and uniform heating. This maximizes lead yield from your feed material (battery paste, dross, concentrates) and promotes efficient slag metal separation in lead smelting, resulting in higher-purity lead bullion and lower metal losses in slag.

4. Comprehensive Pollution Control Integration

Meeting stringent environmental regulations is non-negotiable. Guanma furnaces are designed for seamless integration with advanced fume capture systems for lead rotary furnaces (baghouses, scrubbers) and efficient slag handling solutions, helping you maintain compliance effortlessly.

5. True Customization, Not Just Sizing

We go beyond simple scaling. Guanma provides custom rotary kiln solutions for lead processing, tailoring the furnace diameter, length, refractory profile, burner type (gas, oil, dual-fuel), discharge system, and automation level to your specific feedstock, desired capacity, and plant layout. Need a high-efficiency lead smelting furnace for battery recycling? We specialize in it.

Beyond the Furnace: Guanma’s Commitment to Your Success

Choosing Guanma means partnering with experts dedicated to your long-term productivity:

End-to-End Project Support

From initial concept and rotary furnace design for lead refining through installation, commissioning, and operator training.

Proactive Global Support & Spare Parts

Minimize downtime with readily available technical support and genuine spare parts worldwide.

Proven Expertise

Decades of experience supplying robust industrial rotary furnaces for lead recovery globally.

Guanma Machinery isn’t just another supplier; we are your solution partner for efficient, reliable, and profitable lead smelting operations. We engineer our furnaces to solve the real-world challenges you face daily.

Ready to transform your lead smelting efficiency and reduce costs?

Contact Guanma Machinery today for a detailed consultation and quote on your next high-performance lead smelting rotary furnace.