Battery Hydrometallurgical Recovery Unit Delivered

A European battery recycler, sought to improve recovery rates of nickel, cobalt, manganese (NCM), and lithium from spent lithium-ion batteries, they faced challenges with traditional pyrometallurgical methods: high energy costs, low metal purity, and environmental concerns. The delivery of our Battery Hydrometallurgical Recovery Unit provided a breakthrough, enabling efficient, eco-friendly extraction of critical battery materials.

The Challenge: Inefficient Recycling & Rising Demand

With global EV adoption surging, Needed a scalable solution to process 5,000+ tons of end-of-life batteries annually.

Existing methods struggled with:

Low recovery rates (<70% for cobalt and lithium).

High carbon emissions from smelting.

Complex separation of NCM components.

Our hydrometallurgical technology addressed these pain points while aligning with EU sustainability mandates.

The Solution: Closed-Loop Hydrometallurgical Recovery

The custom-designed Battery Hydrometallurgical Recovery Unit combines leaching, solvent extraction, and precipitation to achieve:

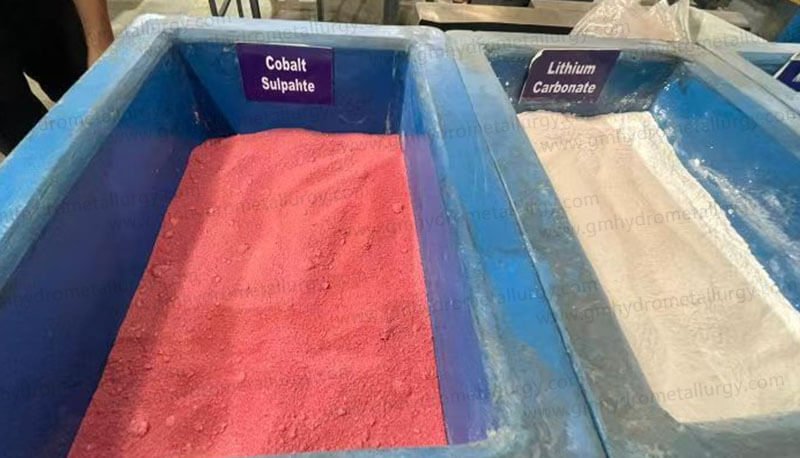

95%+ recovery efficiency for nickel, cobalt, manganese, and lithium.

High-purity outputs (>99.2%) meeting cathode-grade material standards.

Zero wastewater discharge via advanced filtration and water recycling.

30% lower operational costs compared to pyrometallurgy.

Why This Hydrometallurgical Unit Stands Out

1. Precision Separation Technology: Targets specific metals using pH-controlled leaching, eliminating cross-contamination.

2. Modular Design: Scalable from pilot plants to 10,000-ton/year facilities.

3. Carbon-Neutral Operation: Integrates renewable energy compatibility and low-temperature processing.

Long-Term Impact & Industry Leadership

By adopting this sustainable battery recycling solution, Client strengthened its position as a circular economy leader. The recovered materials now supply local EV battery manufacturers, closing the loop in Europe’s green energy supply chain.

“This hydrometallurgical recovery unit exceeded our targets,” said Client Representative. “The ROI was achieved in under 18 months, and we’re now expanding capacity to meet growing demand.”

Guanma Machinery empowers global recyclers and miners with cutting-edge hydrometallurgical systems. Contact us to optimize your critical metal recovery processes today.