Introduction to Modern Electrolytic Recovery

Electrolytic recovery technology has revolutionized how we reclaim precious metals from various sources. Gold silver copper electrolytic recovery machines represent the pinnacle of this technology, offering unprecedented efficiency in metal recycling processes. As we move into 2025, these systems have become more sophisticated, automated, and essential for businesses looking to maximize their return on investment while maintaining environmental compliance.

How Electrolytic Recovery Machines Work

Modern precious metal electrolytic recovery systems utilize electrochemical processes to separate and purify metals from solutions. The basic principle involves passing an electric current through a solution containing metal ions, causing them to deposit onto cathodes in their pure form.

The latest models feature:

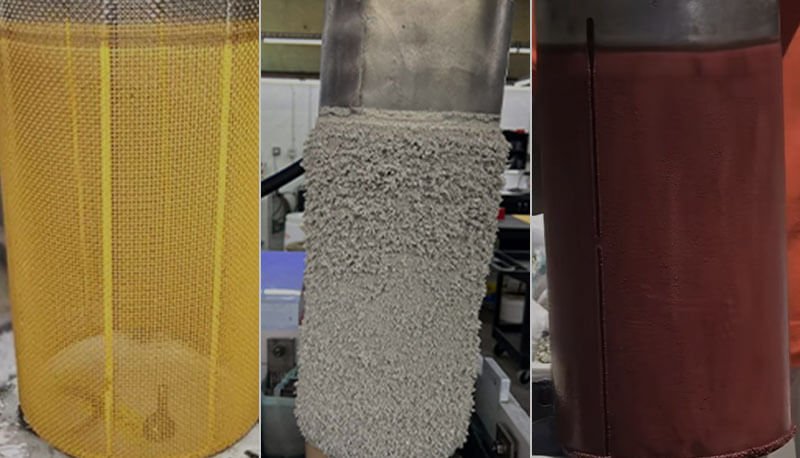

Advanced membrane technology that separates recovery chambers for different metals

Smart sensor systems that automatically adjust voltage and current based on metal concentration

Automated harvesting systems that remove purified metal without interrupting operation

Integrated solution management that maintains optimal chemical conditions throughout the process

Key Benefits of Upgraded 2025 Systems

The newest generation of industrial electrolytic metal recovery equipment offers significant advantages over earlier models:

Enhanced Recovery Rates

Modern systems achieve recovery rates of:

99.9% for gold electrolytic refining

99.8% for silver recovery from photographic solutions

99.7% for copper reclamation from plating baths

Reduced Operating Costs

2025 models feature:

40% lower energy consumption through optimized power management

60% less chemical usage with advanced recycling systems

Minimal maintenance requirements with self-cleaning components

Environmental Compliance

Latest systems include:

Closed-loop water recycling systems

Emission control technology

Automated waste minimization features

Real-time monitoring for regulatory compliance

Applications Across Industries

Electrolytic metal refining machines serve numerous sectors:

Jewelry Manufacturing

Recovery of gold and silver from polishing wastes

Purification of precious metals for alloy production

Electronics Industry

Recovery of gold from connector plating solutions

Copper reclamation from PCB manufacturing processes

Mining and Refining

Final purification of precious metals

By-product recovery from processing streams

Photographic Industry

Silver recovery from fixer solutions

Water recycling for environmental compliance

Choosing the Right 2025 System

Selecting the appropriate high-efficiency metal recovery unit requires considering several factors:

Processing Capacity

Match equipment size to your production volume:

Small systems: 5-50 liters per hour processing capacity

Medium systems: 50-500 liters per hour

Large systems: 500-5,000+ liters per hour

Metal Types and Concentrations

Consider systems designed for your specific metal mix:

Gold-focused systems with specialized cathode materials

Silver recovery machines with optimized chamber design

Copper electrolytic units with high-current capabilities

Multi-metal systems for complex solutions

Automation Level

2025 systems offer various automation options:

Basic manual controls for small operations

Semi-automatic systems with preset programs

Fully automated smart factories with IoT connectivity

Installation and Operational Considerations

Proper implementation of automated precious metal extraction technology requires attention to several aspects:

Space Requirements

Modern systems have compact designs but need:

Adequate ventilation for electrolysis gases

Proper drainage and containment systems

Access for maintenance and cathode removal

Utility Connections

Cost Analysis and ROI Calculation

Investing in 2025 gold silver copper recovery machines requires careful financial analysis:

Initial Investment

Equipment purchase price: $20,000-$500,000+

Installation costs: 10-20% of equipment price

Training and startup expenses: 5-15% of total project cost

Operating Costs

Electricity: $0.10-$0.50 per kilogram of metal recovered

Chemicals: $0.05-$0.20 per liter processed

Maintenance: 2-5% of equipment value annually

Return on Investment

Most systems achieve payback in:

6-18 months for high-volume operations

12-36 months for medium-volume applications

24-48 months for smaller operations

Future Trends in Electrolytic Recovery

The evolution of precious metal recovery systems continues with several emerging trends:

AI and Machine Learning Integration

Predictive maintenance algorithms

Optimization of recovery parameters

Automatic adjustment to changing feed conditions

Sustainability Enhancements

Reduced water consumption through advanced recycling

Lower energy requirements with improved cell design

Complete waste minimization systems

Modular Design Approaches

Scalable systems that grow with your business

Quick-change components for different metals

Plug-and-play expansion capabilities

Conclusion: Making the Right Investment

Selecting the appropriate 2025 gold silver copper electrolytic recovery machines requires careful consideration of your specific needs, budget, and operational constraints. The latest systems offer unprecedented efficiency, automation, and environmental performance, making them valuable investments for any operation involving precious metals.